If you’re an electronics buyer, some days you may feel like Sarah Connor at the end of The Terminator, the classic 1984 movie. Remember the unstoppable Arnold Schwarzenegger, in all metal form, as he relentlessly chased Sarah through that factory of moving equipment? He simply refused to die!

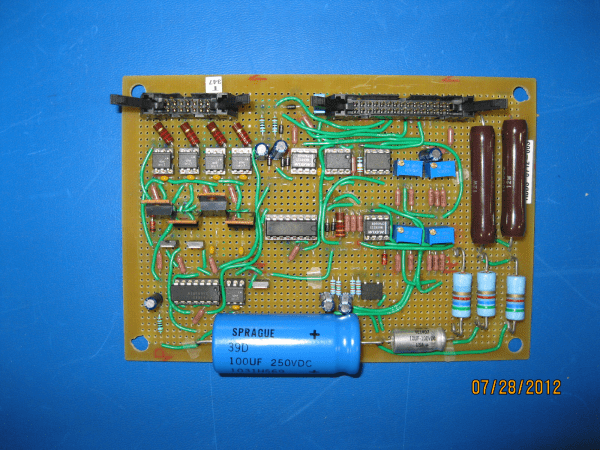

That scene reminds me of most of the legacy electronics out there; they refuse to die, even after the Original Equipment Manufacturer (OEM) stops actively selling them, including them in the product catalog, supporting them, or acknowledging that they exist. I’m kidding about that last one but you get my meaning. Many electronic devices just keep on running, doing exactly what they were designed to do, well beyond their advertised life.

And then, unlike The Terminator, the assembly in the field eventually does expire and one day your company gets a call to replace it. Your sales team springs into action to convince your customer to upgrade to the latest model but she isn’t interested. “No – we can’t afford the time to even talk about it. Just send us another one just like it. Better yet, send me two so I can keep a spare one on the shelf.”

If you happen to be a manufacturing giant, you may be in a position to refuse this order and force your customer to upgrade. But the vast majority of OEM’s don’t have this luxury (if that’s what it really is).

Your sales team flips this request to the customer service department… who calls you, the electronics buyer. And now this unwanted, low priority two-piece order for legacy electronics lands in your lap. Compared to the purchasing activity that you are primarily responsible for, it’s a distraction. The components are likely obsolete, pricing will be a guess, and convincing your Contract Manufacturer (CM) to make room in their production schedule may be tough as well.

You don’t even want to think about the fact that once this order ships, your company has just extended the life of this assembly even further! Sarah may never escape! How will it ever end?

Small Batch Job Shops to the Rescue

Sarah Connor had Kyle Reese; as an electronics buyer, you need a partner too. This partner needs to be motivated to tackle the demand for legacy electronics as an everyday part of their business. A small batch job shop is exactly that.

The ideal job shop for legacy support work:

- Has a staff of component and manufacturing engineers who can assess and interpret old, coffee-stained, red lined drawings when necessary,

- Can research and recommend replacements for obsolete parts quickly and accurately,

- Has a production schedule that is ready and willing to run small batches as a matter of routine,

- Has equipment that is easy to change and dial-in to old and new products alike, and

- Cultivates an environment where their people thrive on diverse technical challenges.

If you’re feeling chased and exhausted from your relentless legacy products, start your internet search with “small batch” or “electronic job shop.”

A Final Word of Caution

It can be challenging to find the right partner for this legacy work, mostly because of the combination of four issues inherent in this business:

- Component obsolescence resource needs,

- Documentation condition and records,

- Fundamental inability to forecast demand by product, and

- These products are – by definition – not going to grow.

It is not difficult to get CM’s to declare their interest in your legacy business. But many OEM’s have had to move their older work once again after their CM “partner” came to realize that only small, unpredictable batches were forthcoming. Watch out for random price increases and/or subtle slips in service responsiveness as clues to this situation.

Find that right partner for your legacy work and you can safely extend the productive lives of many of your products with no threat or fear at all. RBB borrows a line from the Statue of Liberty: “Give us your tired, your poor, your huddled products yearning to be built.”

Are you evaluating a new circuit board manufacturing partner? Check out our one-page checklist which provides all of the questions you should ask as part of your evaluation.

Are you evaluating a new circuit board manufacturing partner? Check out our one-page checklist which provides all of the questions you should ask as part of your evaluation.

Bruce loves to manage change and to encourage working environments where employees and customers thrive. His passion led him to found ODS – a highly practical leadership, trust and communication training firm and blog. He’s a noted speaker, author, active church member and community volunteer. Bruce has led RBB since 2001, becoming Owner in 2007.