You’re an OEM who has developed a solid supplier relationship with an electronics job shop, whether they are local or across the country. The shop has proven themselves to be reliable, responsive, and cost competitive, especially in small batches (the work that many of the larger batch CM’s often avoid). You are happy with your job shop’s performance and want to award them more work. What will you do? Let’s explore a few options.

1. More assemblies

The main thing that distinguishes a small batch job shop from your other good suppliers is that they absorb new assemblies into their mix routinely and with ease. Perhaps you have focused them on one aspect of your portfolio, for example your new product development or legacy products. They’ve earned your trust by building these assemblies in high quality, and they deliver when you need it, despite the lack of a sales forecast.

Now may be the time to entrust more assemblies into their care. Look for additional products in your mix that they could build for you. Good candidates would be those products whose demand is unpredictable, where your current levels of service are suffering, and/or where you are entering a period of uncertainty and don’t want to carry the significant inventory you have in the past. Examples include:

- Second tier product lines that your Sales department supports but does not actively sell.

- Mature products that are reaching end of life.

- Supplemental orders for spare parts.

- Conversions of non-moving assemblies into variations that do.

- Repairs that your company performs that can be better done on the outside.

2. The whole thing

2. The whole thing

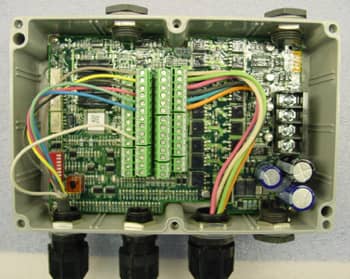

Another alternative is to have the job shop build your complete devices. If they are assembling solely your printed circuit boards today, consider having them do the conformal coating or potting, the associated wiring and cables, the full box-build, and/or X-ray inspection and environmental testing. The more complete your unit arrives, the less you need to further process it in your plant. The real advantage of this option is that your job shop is already efficient in smaller batches; it is often less costly overall for them to finalize the whole assembly than to wedge these incomplete small batches into your own production schedule.

3. Referrals

Unlike large batch CM’s who must naturally be very selective with whom they do business, your electronics job shop partner highly values a broad spectrum of customers – the broader the better. Contrary to industry norms, the risk your job shop partner carries is not in too many customers, but in too few. This is because most of the small batches they build carry unpredictable demand – so the smaller the customer base, the more wildly their total production requirements vary.

Go through your Contact list and make a referral (or two) to your partner. They will be forever grateful. Plus their responsiveness to you may even improve since the more customers they serve the easier they will be able to staff their shop on an ongoing basis. Help them to help you.

4. Give them some larger batches

This option can be very tempting. You may think that you will be doing both parties a favor here, but a word of caution is needed. If your job shop partner is encouraging you to increase your batch size (or to give them your large batch work) this may indicate that what they really want is to “outgrow” the small batch world. They may believe that larger batch sizes will make them more efficient through “saving set-ups” and gaining a smoother production schedule. If this is true then your existing small batches may become less attractive to them in the long run – and the success you’ve established together may erode. It’s a slippery slope.

However, if your motivation is to get the same level of service with your large batches as your smaller batches enjoy today – and you don’t want to jeopardize what’s working well now – then a better approach is to split your current large batches into smaller runs and have your job shop partner treat these in stride. You get to carry less inventory; they get more work. That’s a very good deal indeed.

If your electronics job shop partner has earned the right to more business from you, be sure you are helping your own company in the process. The 4 options described here will do just that, and none of them will swamp your partner such that the service you already depend on will be compromised. The future of the small batch looks bright!

Bruce loves to manage change and to encourage working environments where employees and customers thrive. His passion led him to found ODS – a highly practical leadership, trust and communication training firm and blog. He’s a noted speaker, author, active church member and community volunteer. Bruce has led RBB since 2001, becoming Owner in 2007.