Though RBB's specialty is manufacturing low volume, small batch electronics, we also pride ourselves on being able to say “yes” to just about any PCB circuit board assembly, box build, or control panel requirement in the recurring small batch marketplace.

In today's "Q & A" session, we look to our Lead Panels Technician, Jim Larson, to help explain the complex and sometimes challenging world of panels.

1. Tell Me about Your Electronics Background

I’m a 2009 graduate of North State College, with a degree in Electronic Engineering. After that, I worked at a small company as a bench technician repairing oxygen analyzers. I started at RBB in October of 2010 as an Assembly Tech, then moved to a position as a Test Tech, before being asked to take over the panels area for a retiring employee. In January of this year, we combined the small box build and panels into“Panels and Mechanical Assembly”, which is the area I now supervise.

2. What Does a Normal Day as Lead Panel Technician Look Like?

On a normal day, I will answer three to four phone calls from our customer's engineers, usually answering questions about something we did in the past, or regarding something they'd like to try in their next project, or a progress update on their current project. I then go through a few emails with the same type of questions, however, these are usually internal to RBB.

Next on the list would be Procedure Review and updates. On the small panel build side, we use a procedure to reproduce these panels. It’s a written step-by-step version of the blueprints. So, each time we start a new job I review this with the builder to make sure they understand what they are making and that it is correct to the blueprint. This also gives an opportunity to train fellow builders on how to read prints.

Then I work on the schedule - the order in which our department builds the jobs. When working with panels, some jobs take just a few hours, while others take a few weeks to complete. It’s always a unique balance to make sure we hit the due dates. Along with scheduling is the purchasing of shop supplies. The panels area is different from the rest of RBB's supply procedures in that there are jobs that do not always have an RBB-generated BOM. So, it is very imperative to know the shop supplies needed to build a job.

Some days there are on-site sales calls, where I assist the sales team with any questions and quotes.

The last daily function would be the graphic part of the build. All panels get some kind of tag or label, and we make those with our printer and engraver.

3. How Would You Describe Your Role?

One important job function is to teach and pass on knowledge. Next, would be working with a customer's engineering team and scheduling. With all of the important steps that go into ensuring a panel assembly order goes smoothly such as administrative work, quoting, training, and talking with engineers, I do not always get the opportunity to do as much building as years past, so it is always nice when I can physically build an assembly!

4. What's the Difference between Circuit Board Assembly and Panel Assembly?

To understand the difference between a circuit board and a panel, you first should understand what each does. The simplest panel that I can think of is one that you use every day. It has two wires, a mechanical switch, inside a metal box and controls a load. This panel controls one circuit and it’s in a wall. What is it? It’s a light switch, and it controls 120 volts to the light.

Now, you make a similar circuit on a circuit board with an LED, but it would be at a far smaller voltage, about 1.7 volts. It's important to remember that most circuit boards deal with low voltage. There are exceptions but for the most part, it's 120 volts or under. In addition, circuit boards are built using non-active components like resistors, diodes, and capacitors. The circuits on a circuit board are made to do a task of some kind.

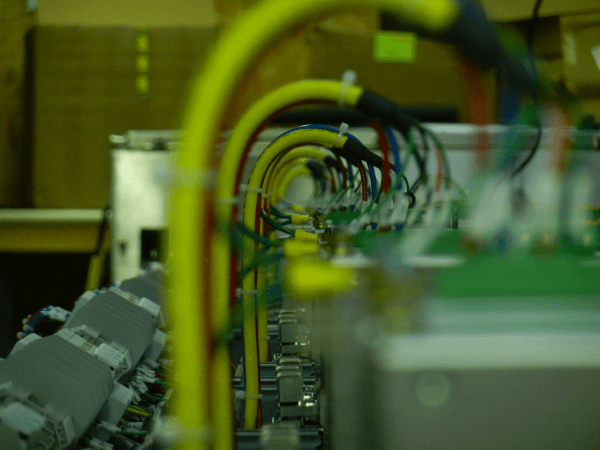

Now let’s look at a control panel. First off, the incoming voltage ranges from 24 volts and up. Most of the ones we build at RBB are in the 240-volt range. Like circuit boards, there are components inside a panel and these contain circuit boards doing a certain task. There are transformers to change voltage, power supplies to regulate voltage, drives to control motors, PLC’s to control the logic. Also inside a control panel, we use a low voltage to control a bigger voltage through the use of relays, motor drives, and SCR’s (solid state relays).

An additional difference is how the components are connected. On a circuit board, the resistors and other components are connected by what is called a trace, which is a thin copper strip in a fiberglass board. Components are soldered into place. In a control panel we do the same thing, only we use wire to make the trace and terminal blocks to make the connections.

So, in the end, we can make this analogy.

“A resistor, diodes, capacitors, are to a circuit board as a circuit boards are to a control panel.”Ultimately meaning that they are the building blocks to make a machine that will do a task or control a function.

5. What is Your Favorite Part of Assembling Panels?

That’s easy to answer. It would be taking a two-dimensional drawing and making it into a machine.

6. What Are the Basic Steps to Assembling a Panel?

- Planning!

- First, start with a layout. This where you are going to put all your components.

- Next would be assembly and mounting of those components.

- Then it would be wiring those components together according to the schematic or blueprint.

- Lastly, we do a basic continuity check to make sure that the wires are connected to the correct terminal blocks.

7. What Equipment Do You Use Most?

We use drills, saws, and a wide range of hand tools.

Diving into the world of panels further highlights the different services that are needed when it comes to electronics manufacturing. It's not just one-size-fits-all. There is always something new. Do you specialize in panel assemblies? If so, what's your favorite part about the panel assembly process? Does it look the same or different than RBB's? Let us know below!