American made since 1973.

Each of our capabilities, whether it be a material we work with or an assembly method, guarantees we remain a leader in a very specific, but extremely important, space within electronic assembly manufacturing.

What are our PCB assembly process steps? We manufacture circuit boards with all standard PCB/PWB substrate materials. We also work with flex circuit, metallic, ceramic, and mixed rigid/flex substrates with lead and RoHS soldering. But that’s only the beginning. View our custom circuit board assembly process flow capabilities.

Save money thanks to our proven, highly customized approach.

Keep your legacy products alive.

Efficiently get your designs built and ready for market.

Industries that need reliable, on-time, high-quality PCBA or control panel products—every time—choose RBB:

|

|

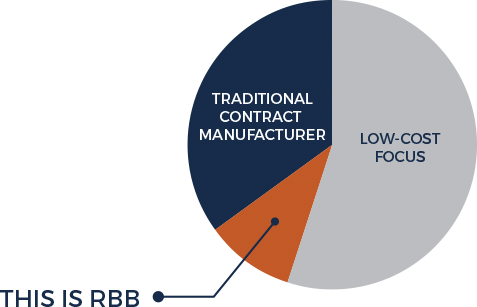

Peace of mind and risk mitigation are just the beginning. Our ability to efficiently manufacture and test recurring jobs shows that we have the custom processes and extensive knowledge base that traditional circuit board manufacturers just don’t have—making us the experts to turn to if you need many electronic assemblies in small, medium, and large quantities. Find out how we have helped eliminate headaches for many of our clients by reading these case studies.

American made

since 1973.