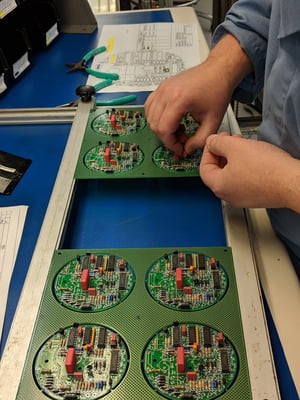

We've optimized our facility to support recurring electronic assembly needs. It strategically makes everything we do more efficient, directly benefiting your PCB assembly projects.

Unlike typical contract manufacturers, where efficiency is tied to long production runs, RBB operates differently. Our facility is streamlined for both large-scale and small-volume electronic boards. We ensure that every job, regardless of size, is accommodated efficiently, making us a versatile partner for all your circuit board manufacturing needs.

Our approach to lean manufacturing is tailored to our high-mix, recurring electronics assembly environment. We've implemented custom lean processes across our facility, ensuring rapid yield for all jobs. The RBB approach guarantees lower costs and quicker delivery for your printed circuit board projects.

RBB uniquely applies lean manufacturing techniques to its recurring, high-mix environment. Constant product changeover means we must process jobs quickly through our facility. Application of our custom lean processes enables our team to be more efficient, guaranteeing your printed circuit board costs are low and delivered quickly.

We efficiently position our workforce and resources to the busiest areas in our facility, minimizing time spent moving between tasks. This flexible approach allows us to adapt and improve our processes for even greater efficiency. Enhanced by cross-training and effective communication, our team optimizes capacity to its fullest. Below are key statistics that illustrate our capabilities in relation to our team and facility:

RBB is your reliable partner for electronic assembly services. We precisely handle each diverse order to meet your needs.

American made

since 1973.