Before we can answer that (how to best serve your electronic manufacturing customers), first let me ask, 'Who are your customers?'. At our small batch electronics job shop, it sounds like an easy question to answer…anyone who has circuit board assemblies they need manufactured in small batches by a premiere job shop.

But stop and think how many of your employees have direct interaction with your customers. Here at RBB Systems the sales and engineering staff frequently discuss assemblies, drawings, materials and orders with our customers. What about the rest of us? How can we better serve our customers? By better serving each other, of course!

One important aspect of being a premiere electronics job shop is making sure that each employee is treated like we treat our customers. Some areas of this are pretty obvious. Human Resources has direct contact with each employee making sure their employment needs are met, assisting with payroll, insurance, safety and serving as a counselor. Organizational Leaders are another. Responsible for onboarding and training, this position serves each employee by ensuring they are fully capable of performing their job duties and has the tools to succeed.

Let’s explore some other not so obvious areas:

- Purchasing? – Sure. Our buyers do their utmost to not only purchase quality parts at the best price, but each part must be in-house to meet the production schedule start-times. This allows the Material Specialists in the stockroom time to pull and prep each part to customer specifications.

- Accounting? Yep! We have an open book policy. Our daily dashboard is posted for all to see, digest and ask questions. Timely and accurate reporting ensures that our 55 business folks understand the impact that new orders have on their production schedule or what the effect the overall gross margin has on reaching our profit goals both this month and annually.

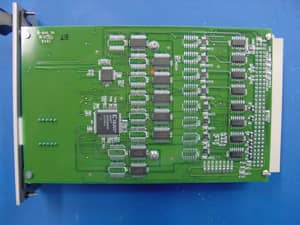

- Engineering? You betcha! From our manufacturing to our CCT engineers, they are serving our employees on a daily basis. It’s not unusual to find production staff discussing a customer’s drawings or color sheets with the engineers for clarification on the best way to build a quality product. The operators of our SMT, Axial, Selective Solder, X-Ray and various other pieces of equipment rely on the knowledge and training of our manufacturing engineers to assist with setups, maintenance and running the machine for optimal performance.

- Production/Stockroom Staff? Absolutely! Before each job starts, the production/stockroom staff meets to discuss the intricacies of the job, and how best to perform each step in the assembly process to ensure a quality product for our customer.

When you put the whole package together, everyone at RBB Systems practices good customer service for each other and most importantly, our customers. That’s one of the many reasons we call ourselves The Premiere Electronics Job Shop.

As Accounting Manager and Treasurer, Micki is responsible for all financial aspects of the company. She works daily with CCT's, outside accountants, attorneys and bankers to ensure stability in company cash flow, and financing capital projects. Additionally, Micki is an avid birder and wildlife lover.