RBB Systems' Expertise in Custom Integration

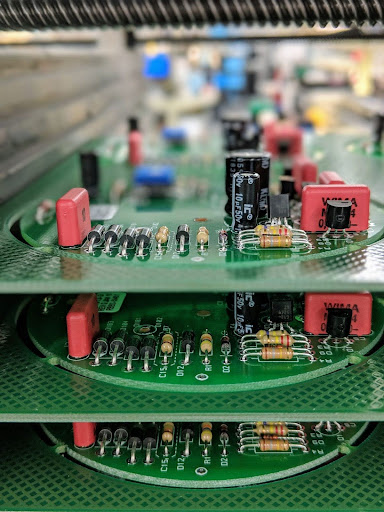

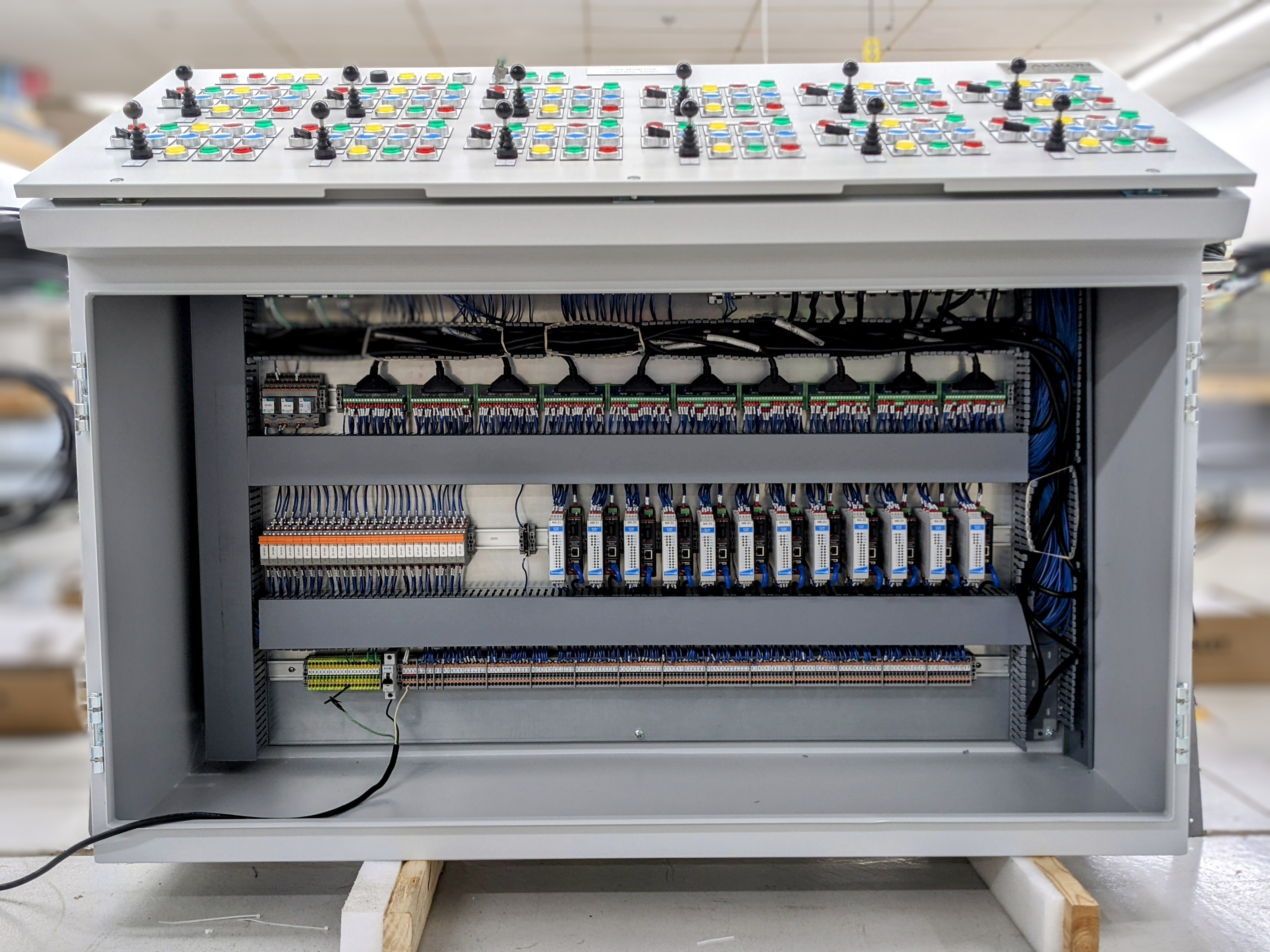

Box-build assemblies and industrial control panels are key to delivering integrated, ready-to-use solutions. These systems often have greater complexity than standard PCB assemblies because they involve not just the board but also enclosures, wiring, cable harnesses, mechanical integration, and final testing. Meeting specific customer needs with box-build solutions requires a high degree of flexibility and customization. However, it’s essential to understand the limitations of this process, particularly in regard to the influence a company like RBB has on design, component selection, and assembly.

At RBB, we don’t design or build panels or box builds ourselves; rather, we build to our customers' specifications. Most of the time, our customers provide all or most of the parts required for the assembly. We can suggest substitutions to the bill of materials (BOM), but we will not make changes to the build without customer approval.

In this blog, we’ll discuss why Box-build assemblies and industrial control panels are key to delivering integrated, ready-to-use solutions With solutions, benefits, and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits. At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.