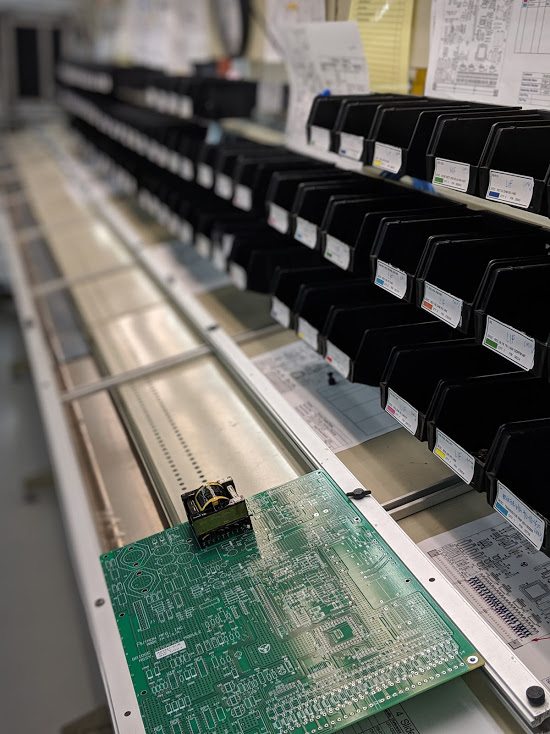

Unlike companies who move all at once from one product generation to the next, many OEMs base their value and reputation on customizing their product offerings to various clients and applications. It’s in their DNA to tweak and expand designs to deliver exactly what their customers need.

This strategy can be very effective, but can come with a natural consequence: a wide portfolio of legacy products that require active support for many years.

Fortunately, the right contract manufacturing partner can help meet the challenges that come with legacy products. Here are some examples of some of those challenges.