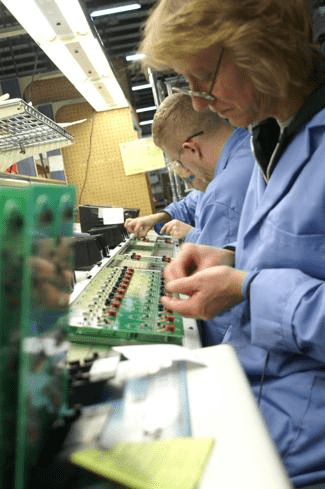

Design for Manufacturability

Design for Manufacturability (DFM) is the process of designing your product so that it can be produced easily and quickly. A few adjustments can help you get your new product to market before your competition, and help you meet your delivery schedules! The fewer steps in the electronics manufacturing process means less time between ordering and receiving your product.