They go together like oil & water, fire & ice, electronics & moisture. Some things just don’t pair well. In this time when electronic components are hard to find, we need to protect the parts we have. All electronic components have a certain level of sensitivity to moisture- some more than others. RBB is working hard to source, store, and protect your PCB assembly and components through all stages of the assembly process. By protecting your assembly from moisture, and watching for moisture issues, we are making sure your mission-critical assemblies are ready to work for you.

Whether you are shopping for a new car, a pair of shoes, or a contract manufacturer, the quality of the item or service matters. Where you spend your money is important and the product you receive should be worth what you pay for! Most companies, brands, or products say they hold high standards and good quality, but do they? There is inherent skepticism when a company claims to have “high-quality,” since that value can be characterized and defined in different ways.

But at RBB, our first-rate service and products are something we are proud of, and we can prove it!

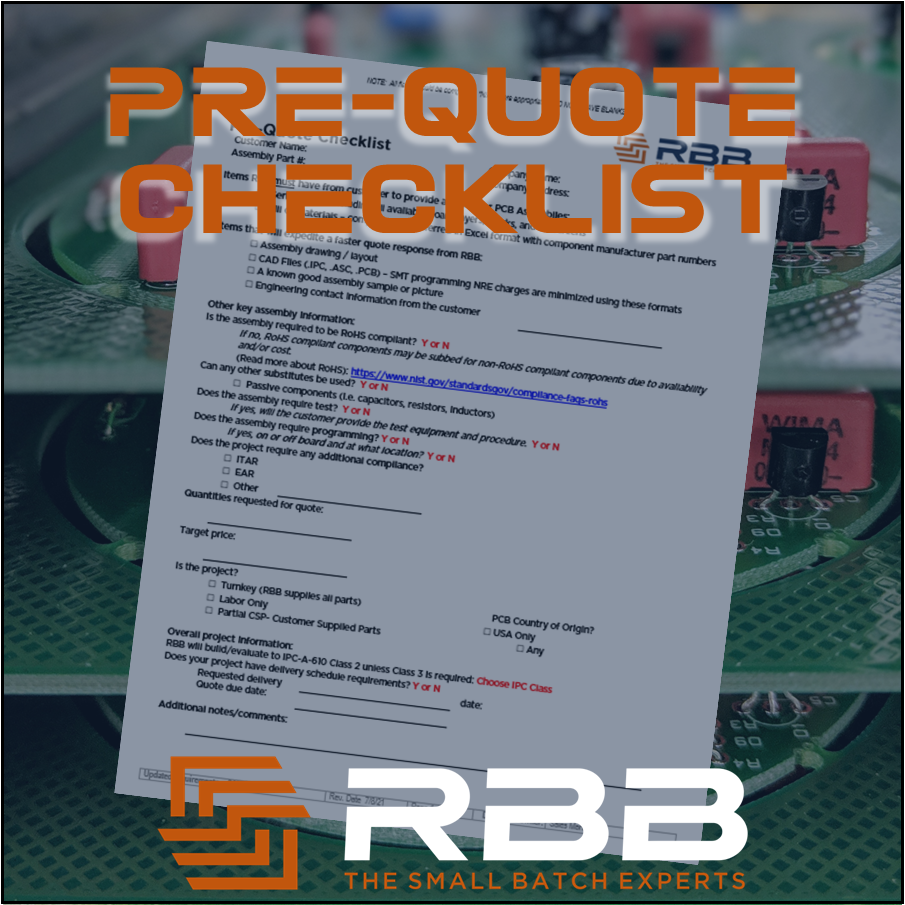

What do a baby food brand, an explosive device, and a pre-quote checklist all have in common? While this sounds like the start of a bad joke or a questionable Google search, these are just three ingredients for a successful printed circuit board assembly proposal. You may be asked to provide the Gerber Files, BOM, and specific project details when requesting a quote from RBB for your PCB project.

The Gerber Files and BOM (Bill of Materials) need to be reviewed for a PCBA to be quoted. The Pre-Quote Checklist is a convenient resource created by the team at RBB to simplify the quoting process.

RBB's August 2021 Lunch & Learn Series - Virtual & In Person!!

We are pleased to announce that our August Lunch & Learn will be a hybrid format- available both in-person & virtual.

Registration is now open for RBB's 2021 Lunch & Learn Series! Each session includes a hands-on presentation, FREE lunch (in person participants only), networking, and RBB facility tour.

All sessions will be held at RBB (1909 Old Mansfield Road, Wooster, Ohio 44691) & virtually.

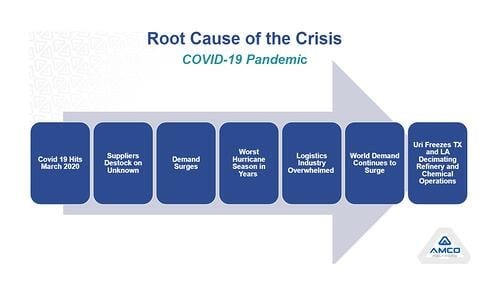

At RBB, our customers are our first priority. As our country continues to recover from the impact of the pandemic, we wanted to reach out to share the challenges we (and many other businesses) are facing. There have been significant raw material shortages and supply chain issues which are contributing to extended product lead times, as well as price increases. As a result of these challenges, you may see some price increases along with varying lead times and product availability. Delivery commitments are given in good faith, based upon the best information present at the time of quotation, but may change due to conditions beyond our control.

Registration is now open for RBB's 2021 Lunch & Learn Series! Each session includes a hands-on presentation, FREE lunch (in person participants only), networking, and RBB facility tour.

All sessions will be held at RBB (1909 Old Mansfield Road, Wooster, Ohio 44691) or virtually.

All are welcome to attend- please pass this invitation to your team members & colleagues!

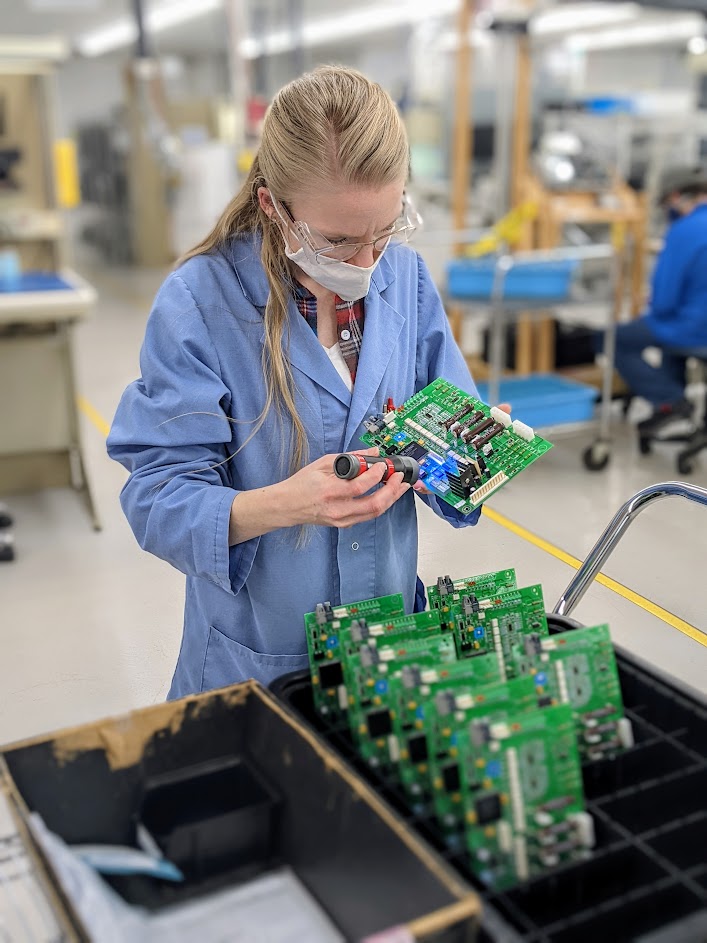

Does your PCBA manufacturer have heroes? At RBB, we do - every day!

One of our core values is "Move Heaven and Earth." This is how we live our daily lives. We swarm to the need each and every day, getting our small batch printed circuit board and industrial control panel customers what they need when they need it.

We have already hosted three great sessions in our 2019-2020 Lunch & Learn series, "How to Save Money in a High-Mix, Low-Volume World." Our next session, titled The IoT in the High-Mix, Low-Volume World, will be presented by Ed Yenni, President, Logisync via Zoom on October 20.

.png)