To create a strong, rewarding experience with an outsourced PCB assembly manufacturer, we recommend following these 4 tips:

"How to Save Money in a High-Mix, Low-Volume World"

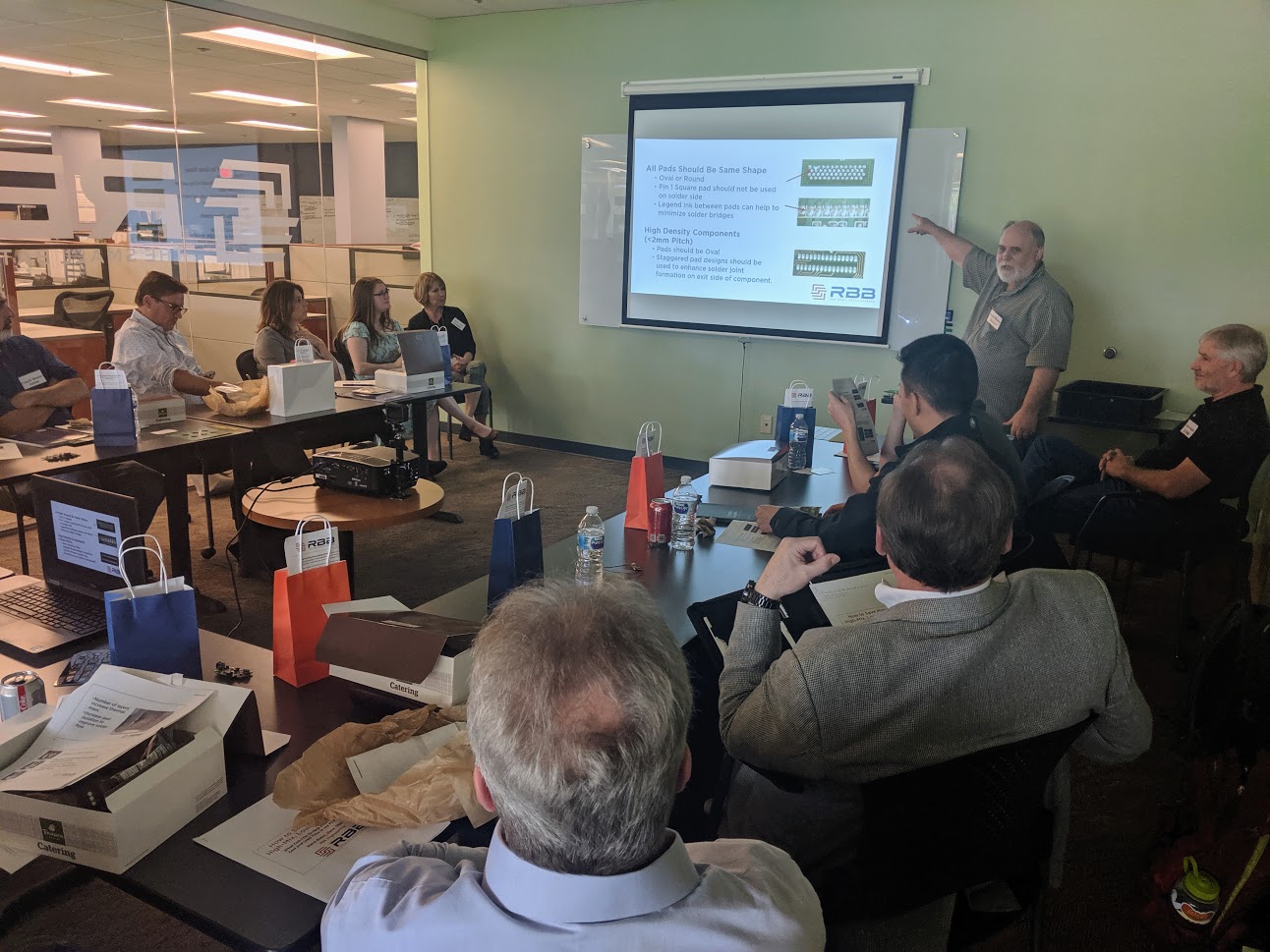

After a great first session in October, preparations are underway for the second installment of RBB's 2019-2020 Lunch & Learn series. This session, Current Industry Trends in the Low-Volume World, will be presented by Norm Lelless of Future Electronics.

All are welcome to attend- please pass this invitation to your team members & colleagues!

The overall goal of this series will be to educate RBB's partners on how to save money in our high-mix, low-volume PCBA industry. Each session includes a hands-on presentation from RBB team members or suppliers, FREE lunch, networking, and a facility tour.

"How to Save Money in a High-Mix, Low-Volume World"

After a great first session, preparations are underway for the second RBB will host a four-part lunch & learn series quarterly in 2019-2020. The goal of this series will be to educate RBB's partners on how to save money in our high-mix, low-volume PCBA industry. Each session includes a hands-on presentation from RBB team members or suppliers, FREE lunch, networking, and a facility tour.

All are welcome to attend- please pass this invitation to your team members & colleagues!

Visual Inspection and Small Batch Electronics

How can a contract manufacturer ensure that it is providing its small batch electronics manufacturing client with the highest quality product when functional testing is not an option? In an effort to reduce costs, many customers will specify that a visual inspection of their completed assembly is to be the final quality control measure prior to shipping. Some of these assemblies can be pretty complex, consisting of hundreds of surface-mount and through-hole components. Each component and its associated solder joints (or another connection method) must be examined. It requires a team of well-trained, dedicated professionals with impeccable attention to detail to successfully complete this requirement.

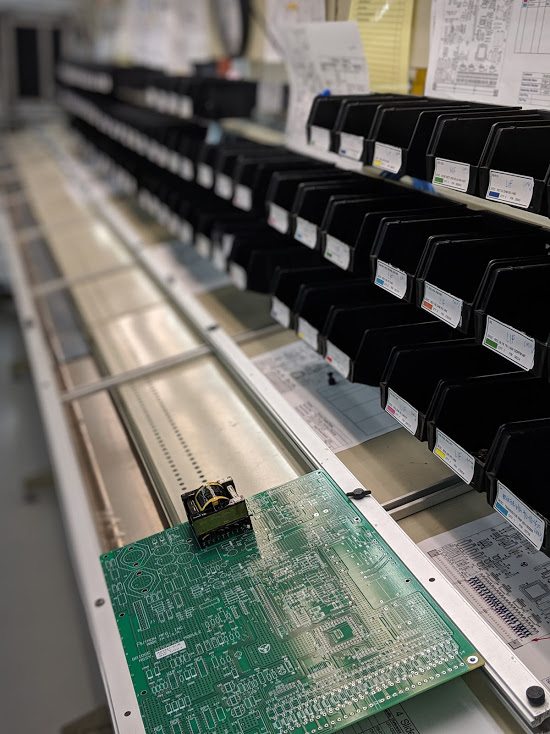

In the EMS industry, the term high-mix, low-volume (HMLV) refers to CMs or OEMs who change over production between assemblies and processes much more often than their low-mix, high-volume (LMHV) counterparts. HMLV shops convert their lines to different assemblies rapidly (hours or minutes) and frequently (several shifts or days). Note that the opportunity for error rises as batch size decreases.

By contrast, LMHV production runs can last weeks or even months between change overs. It’s a different animal altogether.

RBB builds many hundreds of unique assemblies annually and most weeks introduces multiple new assemblies. It's rare that RBB runs a batch large enough to consume an entire shift of time, much less a few shifts!

Culture is central at RBB. We strive to be different, and it is noticed by our team. Last year, we had a team member leave RBB. While this happens frequently in most companies, what’s unusual is that he fought to come back.

Brian Thomas joined the RBB team in 2010. In 2018, he had a job offer. Brian thought hard about this new offer, which included a nice pay raise and sign-on bonus, and ultimately decided to take it. But after only three months at the new job, he started to wonder if what he was promised was really worth the change.

Do you spend days tallying parts during an annual inventory count? Are you shutting down your shop floor for days just to get decent counts? If so, there's an alternative inventory management method that will eliminate the need to shut down production and also deliver better results.

This alternative method is known as cycle counting, and whether you’re a global manufacturer or a privately held company, you may stand to benefit from it. In fact, at RBB we've experienced numerous benefits since we've started to cycle count inventory. Most Importantly, cycle count allows RBB to provide more reliable scheduling and delivery to our clients.

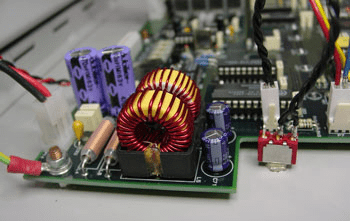

The development and building of a circuit board assembly can range from a very simple to a highly complex design.

At RBB, all boards, regardless of complexity, undergo a full visual inspection of the components as well as a complete check of the step-by-step instructions on the build. We also offer our customers the option for more advanced functional testing.

.jpg)