To create a strong, rewarding experience with an outsourced PCB assembly manufacturer, we recommend following these 4 tips:

Bruce Hendrick

Recent Posts

Trust Culture: Can We Level with Each Other Here?

No, just no: virtual collaboration is not the same as doing so in-person; it’s not even a close approximation. The idea that online tools can replace authentic interpersonal communication is a delusion. I teach trust, and I must level with you about this.

Core Values

It's crunch time for all of us in this time of national emergency. It's at a time like this that we see what we are really made of. RBB is built on our Core Values (CV). They are the hallmarks of everyone at RBB, our DNA. We recognize fellow members of the RBB family because each of us lives the CV’s on a daily basis. Our team continues to swarm to get our clients what they need when they need it. It's the RBB way, and we're grateful to be still allowed to do it.

Unlike companies who move all at once from one product generation to the next, many OEMs base their value and reputation on customizing their product offerings to various clients and applications. It’s in their DNA to tweak and expand designs to deliver exactly what their customers need.

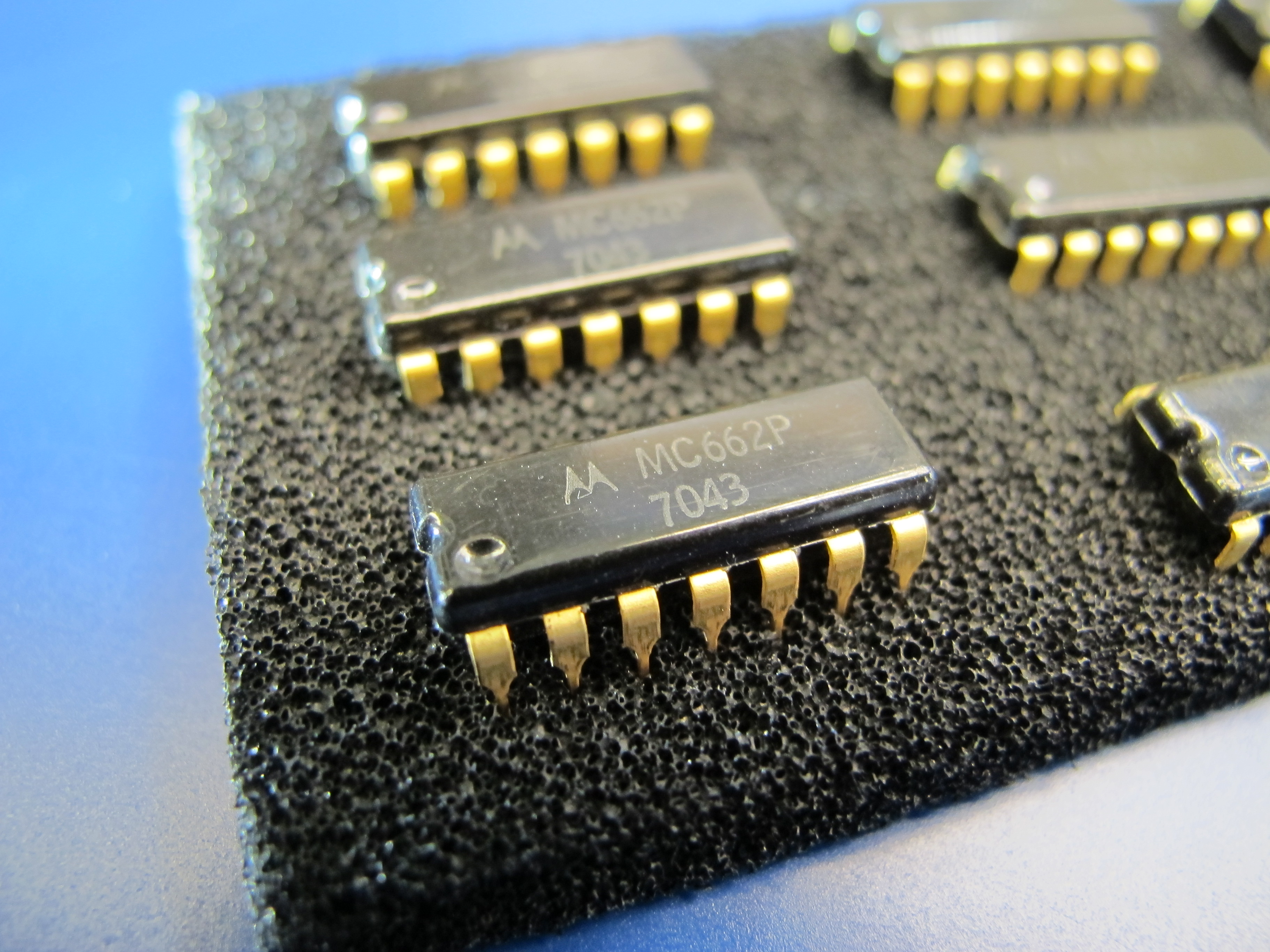

This strategy can be very effective, but can come with a natural consequence: a wide portfolio of legacy products that require active support for many years.

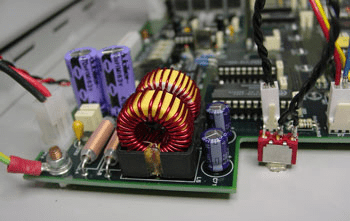

Fortunately, the right contract manufacturing partner can help meet the challenges that come with legacy products. Here are some examples of some of those challenges.

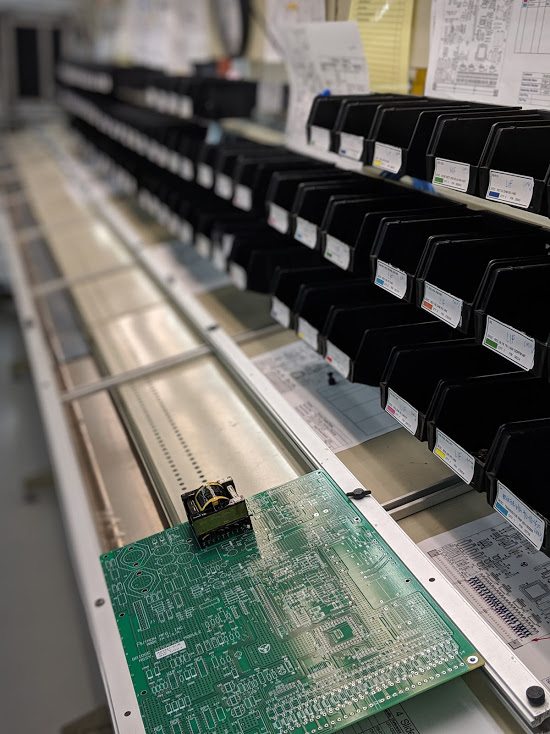

In the EMS industry, the term high-mix, low-volume (HMLV) refers to CMs or OEMs who change over production between assemblies and processes much more often than their low-mix, high-volume (LMHV) counterparts. HMLV shops convert their lines to different assemblies rapidly (hours or minutes) and frequently (several shifts or days). Note that the opportunity for error rises as batch size decreases.

By contrast, LMHV production runs can last weeks or even months between change overs. It’s a different animal altogether.

RBB builds many hundreds of unique assemblies annually and most weeks introduces multiple new assemblies. It's rare that RBB runs a batch large enough to consume an entire shift of time, much less a few shifts!

RBB’s whitepaper on how small batch electronics affects the OEM-CM relationship

Very often OEM’s struggle to effectively manage large portfolios of small batches of custom electronic assemblies. That’s why I tackled the topic in the Whitepaper, “Market Dynamics facing OEM’s with Large Portfolios of Ongoing Small Batches.”

I recently gave a short talk on leadership transitions—in particular, the handoff from one chief executive to the next—at the Small Giants Summit in Detroit. Since joining RBB in 2000, I’ve been on both sides of this coin. I offered a number of hard-won, personal lessons to this enlightened audience of business founders, owners, CEOs, and up-and-comers.