Unlike companies who move all at once from one product generation to the next, many OEMs base their value and reputation on customizing their product offerings to various clients and applications. It’s in their DNA to tweak and expand designs to deliver exactly what their customers need.

This strategy can be very effective, but can come with a natural consequence: a wide portfolio of legacy products that require active support for many years.

Fortunately, the right contract manufacturing partner can help meet the challenges that come with legacy products. Here are some examples of some of those challenges.

5 Challenges with Legacy Devices

(and how the right contract manufacturing partner helps overcome them)

1. Inventory Planning.

Knowing what – and how much – to keep in stock is a perpetual guessing game. You need a partner who can flex quickly to build your small batches of legacy electronics. The right contract manufacturer doesn’t impose pressure to forecast demand. Instead, they rapidly build exactly what is needed at the time and no more. This matches your design philosophy by supporting as wide a product portfolio as you want.

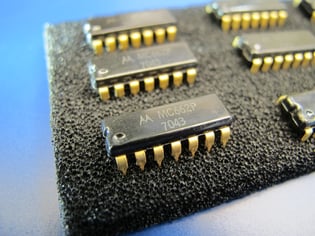

2. Component Obsolescence.

In legacy work, this comes with the territory. Find a partner who scours the world to find components, anticipates supply problems, and recommends replacement parts (with your approval) when needed. The right contract manufacturer owns this challenge alongside you and doesn’t simply toss the obsolescence problem back in your lap.

3. Product Conversions.

Somebody made a bad guess and now you’re holding stock of a legacy product that isn’t moving. Or the wrong contract manufacturer forced a last-time-buy on you. A good legacy partner will convert these assemblies into another version for you, on-demand, in the batch size you need so you can free up your cash.

4. Technical Attention.

Your engineers are busy designing the next generation product line(s) and have little time to devote to supporting the older ones. Or perhaps you bought a business/product line and its development expertise is long gone. The right contract manufacturing partner fills in these gaps by paying attention to quality and manufacturing issues on your behalf – and involving you only when needed to assure continuous supply.

5. Going In Alone.

You would have preferred not to build your legacy or other small batches but felt forced into it because of poor service in the past from more traditional contract manufacturers. The right partner has helped OEMs like yours reduce major cost and hassle by giving them the confidence to get out of inefficient and expensive in-house manufacturing of older, infrequent systems.

For an example of how RBB has helped one such OEM with their legacy support challenges, download our case study.

When you find the right contract manufacturer, you can safely extend the productive lives of many of your products with no threat or fear at all. Every legacy batch hits RBB's production schedule with the same high priority as all our other jobs.

For more reasons why our clients choose us, read the Top Ten Reasons to Choose RBB.

The post was originally published Oct. 19, 2016.