In the EMS industry, the term high-mix, low-volume (HMLV) refers to CMs or OEMs who change over production between assemblies and processes much more often than their low-mix, high-volume (LMHV) counterparts. HMLV shops convert their lines to different assemblies rapidly (hours or minutes) and frequently (several shifts or days). Note that the opportunity for error rises as batch size decreases.

By contrast, LMHV production runs can last weeks or even months between change overs. It’s a different animal altogether.

RBB builds many hundreds of unique assemblies annually and most weeks introduces multiple new assemblies. It's rare that RBB runs a batch large enough to consume an entire shift of time, much less a few shifts!

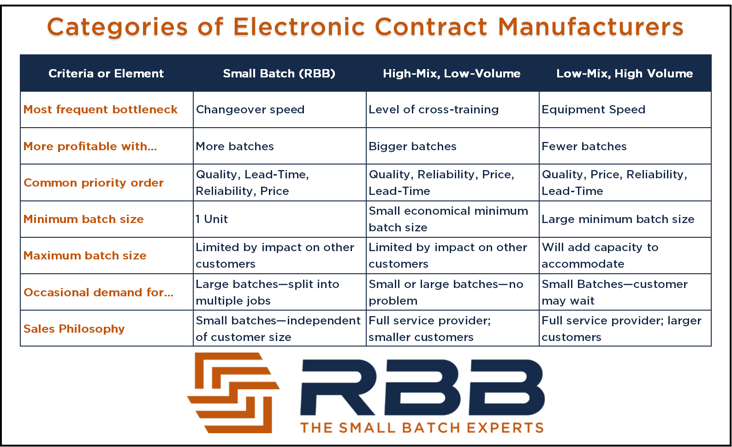

Take a look at the following comparison:

Another item that distinguishes RBB from our HMLV cousins is that these business leaders often consider success itself as growing into a large-volume operation. They want to grow out of the low-volume work. And they see new opportunities as attractive provided they’re on that path. RBB, on the other hand, pursues growth not by increasing batch size but by serving many more clients and assemblies. This provides a rare and much-needed service to the industry – many clients and applications simply do not and will not demand high-volume service. Ever.

Exclusively small batch shops like RBB target a different goal. Success in their chosen niche is only achieved through careful optimization to build small batches quickly, profitably, repeatedly, and routinely. This is not compatible with running large jobs through the same production operation. As a result, the best opportunity for RBB to sustain long term growth is to attract more and more clients that need specialized services. The more successful they are, the more it reinforces their operational excellence with small batches.

This market dynamic is good for all parties involved. The OEM client has more choices of CMs with specialties to suit his unique needs. RBB sticks to what they do best and get even better over time. The HMLV firm can build its base of customers and grow with them into the higher volume arena. And the LMHV business can focus on its sweet spot, knowing that smaller customers will be well-cared-for by the other industry providers. Everybody wins.

Bruce Hendrick has been a leader of major change in corporations and small business alike for the past 30 years; he's the owner of RBB and Building Trust, LLC; noted speaker, author, and active community volunteer.

Are you an OEM evaluating a new circuit board manufacturing partner? You can also check out our one-page checklist which will give you all of the questions you should ask as part of your evaluation.