WOOSTER, OH— January 2025 — RBB, a trusted leader in electronics manufacturing since 1973, is helping manufacturers achieve precision, reliability, and efficiency with its Custom Industrial Control Panels. Designed to meet the diverse and complex needs of modern manufacturing, RBB provides turnkey and labor-only solutions, ensuring customers receive high-quality, fully compliant control panel assemblies.

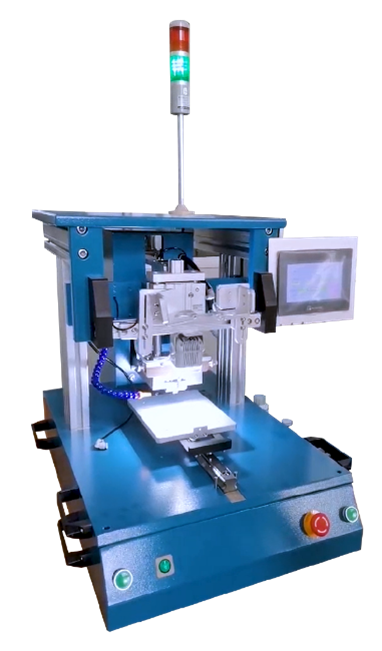

Wooster, OH— February 2025 — RBB, a trusted leader in electronics manufacturing since 1973, is proud to announce the acquisition of the Fancort Industries PHM1-1 Hot Bar Solder Machine, enhancing its ability to tackle complex soldering applications with precision and reliability.

The new PHM1-1 Hot Bar Solder Machine provides precise, high-quality soldering capabilities, allowing RBB Systems to efficiently manage intricate assemblies and challenging builds. Initially acquired to assist a valued client with a demanding project, the addition of this equipment demonstrates RBB’s commitment to “moving heaven and earth” to meet customer needs.

Driving Efficiency and Innovation:

Today, assembly manufacturers are being asked to deliver products where the focus is on efficiency and innovation. Leading manufacturers are adopting best practices to bring production processes up to speed, adopt modern technologies, and build a culture of continuous improvement to remain competitive. Not only do these strategies help improve product quality, they also increase customer satisfaction and culminate long-term business success.

In this blog, we’ll explore some of the top practices from leading assembly manufacturers and highlight real-world examples of success stories that can inspire others in the industry. With solutions, benefits, and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits. At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.

RBB Celebrates the Retirement of Wayne Reising, Longest Serving Team Member

Wooster, OH – January 2025 – RBB, a leading provider of custom electronics manufacturing, announces the retirement of Wayne Reising, Industrial Control Panels Assembly Specialist, after an extraordinary career spanning 47 years and 7 months. Reising holds the distinction of being RBB's longest-serving employee, leaving a legacy of dedication, excellence, and mentorship that has shaped the company’s culture and operations for nearly half a century.

USA Manufacturing Benefits:

When sourcing circuit board assembly and components, manufacturers are faced with a critical decision: should they opt for overseas suppliers to cut costs, or should they choose the reliability and high standards offered by domestic manufacturers?

At RBB, we believe in the inherent advantages of choosing a USA-based manufacturer, and we are proud to offer services that exceed what offshore manufacturers can provide.

This blog will explore the many benefits of partnering with a USA-based company in the electronics manufacturing industry. With solutions, benefits, and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits. At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.

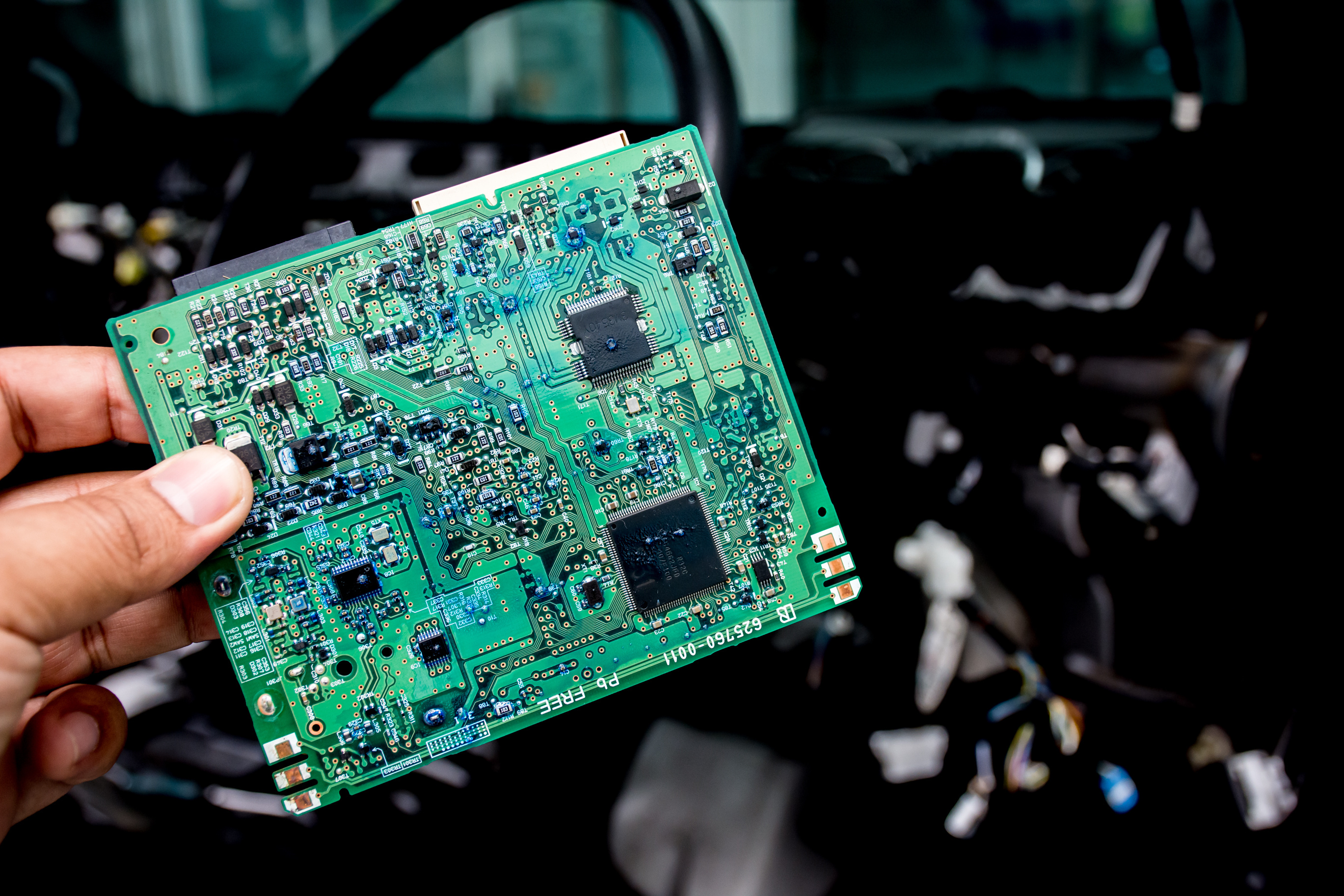

Prototyping to Production:

Every electronic assembly project follows a carefully orchestrated path from early concept to final product. With the ever-increasing demand for high-quality electronic assemblies, companies require trusted partners that can navigate the complexities of prototyping, component sourcing, assembly and testing with precision and skill.

RBB’s extensive experience in electronic assembly services make us a trusted resource for these needs, especially when delivering unique assemblies and handling new market demands

This blog will explore navigating the assembly process from prototyping to production in the electronics manufacturing industry. With solutions, benefits and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits. At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.

Better Service and Results:

In today’s competitive market, businesses are always on the lookout for ways to cut costs and still get high-quality results. While this is true of many things, it is not the case for circuit board assembly, and a low price does not mean that you are getting the best value. At RBB, we believe that true value goes far beyond the initial cost, and we strive to provide our clients with a level of service that ensures long-term success.

This blog will explore the real meaning of value in the electronics manufacturing industry with solutions, benefits and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits. At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.

Understanding Compliance:

In the electronic assemblies manufacturing industry, navigating regulatory requirements is essential and often required for manufacturing success. Understanding standards and certifications like RoHS, REACH, UL, and IPC can be overwhelming, but it is crucial for manufacturers to ensure their products meet the necessary regulations. As detailed in this article, RBB excels in quality and compliance, including regulatory compliance.

This blog will explore compliance and regulatory requirements in the electronics manufacturing industry with solutions, benefits and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits.

At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.

Tailoring Solutions

Custom electronics manufacturing is a great chance for businesses to design and develop products that will meet their needs in the best way possible. This is because when a company works with a specialized manufacturer, it is able to achieve flexibility in design, scalability in production and differentiation in the market.

This blog will explores tailoring custom electronics manufacturing with solutions, benefits and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits.

At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.

Streamlining Production

In today's fast-paced business environment, efficiency and quality are paramount. One effective strategy to achieve these goals is by leveraging turnkey assembly services. By outsourcing non-core functions like assembly, businesses can focus on their core competencies, reduce costs, and improve overall productivity.

This blog will explores streamlining production and the advantages of turnkey assembly services and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits.

At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.