Challenges in Turnkey Assembly Projects: Ensuring Smooth Design Specifications

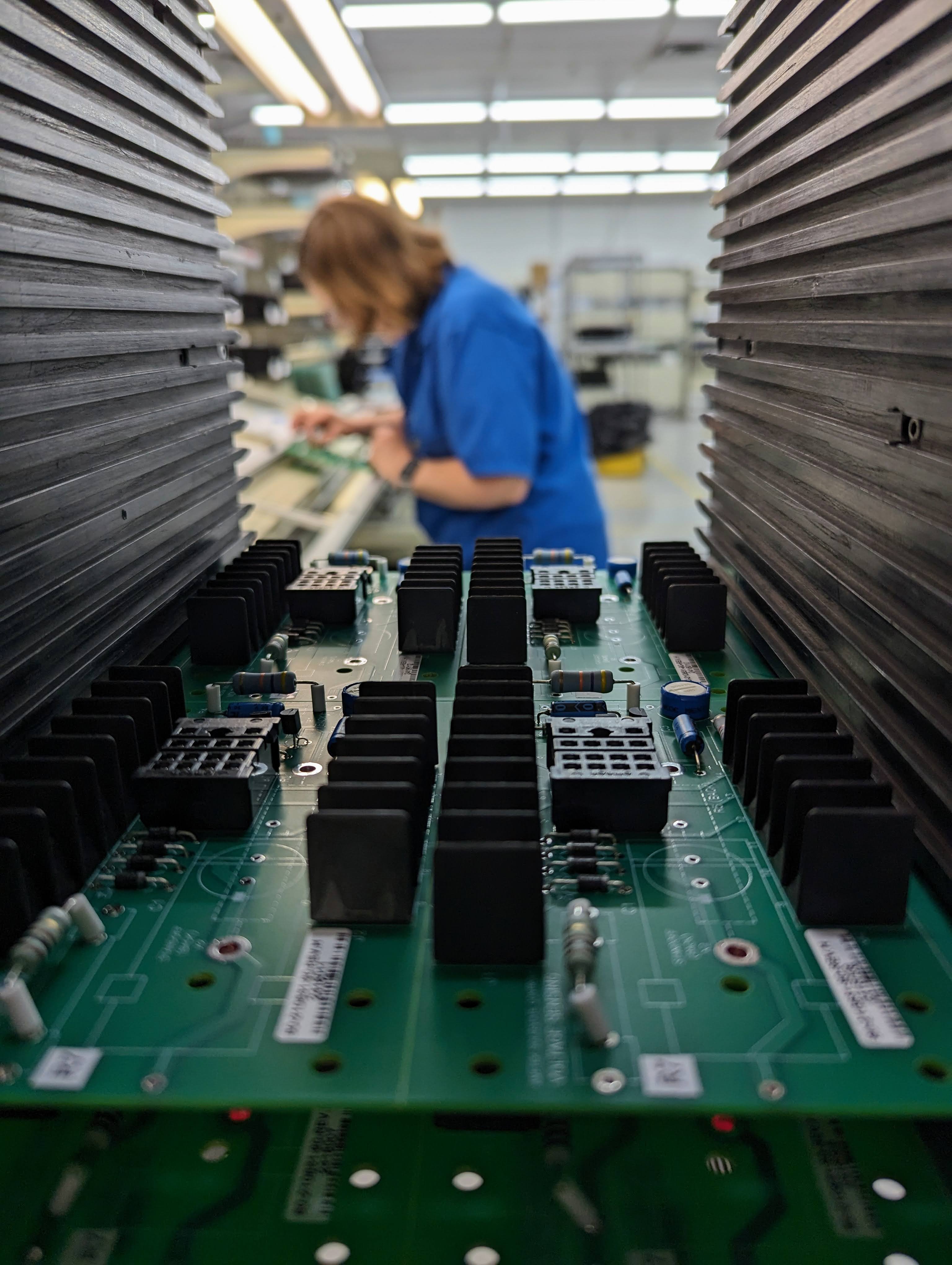

We understand the significance of clearly defined design specifications in ensuring the success of a turnkey assembly project. However, we recognize that challenges may arise when design specifications are not adequately defined or are subject to frequent changes. These challenges can lead to confusion, delays, and rework, ultimately impacting the project's timeline and budget.

To tackle these issues, it is crucial to establish a clear and detailed design specification at the project's outset, including comprehensive documentation of requirements, materials, and performance expectations.

Additionally, maintaining regular communication and collaboration with the assembly team is vital to ensure the design specifications are well understood and effectively implemented.