Getting Away

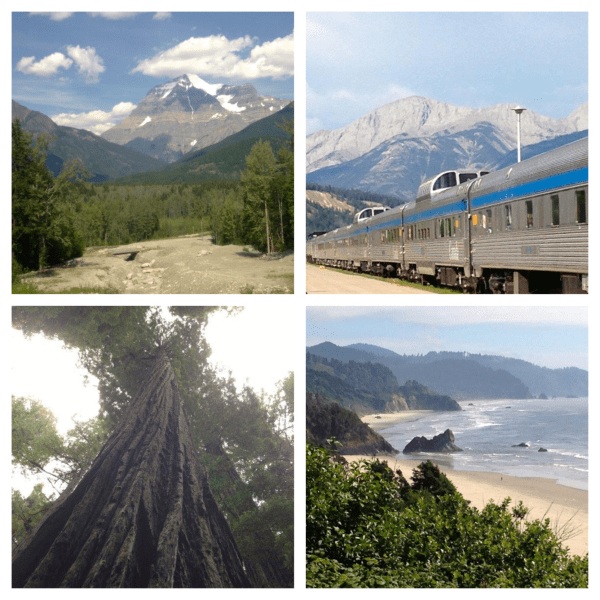

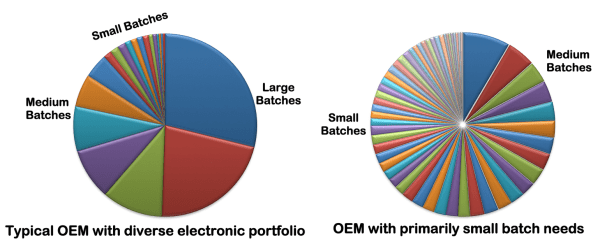

My wife Donna and I just returned from a 3-week bucket-list kind of trip. We met up with Donna’s parents and took the train from Toronto, Ontario, across Canada to Vancouver, British Columbia. It was a beautiful trip filled with awesome scenery, relaxed visiting, and first class meals.