When SmartBusiness Cleveland Magazine honored RBB Systems with its 2010 Evolution of Manufacturing Award, it drew attention to the growing separation of RBB’s business model from the rest of the pack of reputable contract manufacturers. All the way back in 2008, RBB had announced that it had “left the field” of large batches permanently behind. Since these high volume (gravy) runs had always been the Holy Grail, SmartBusiness was intrigued.

Recently, I came across the article "Social Media- Finally Ready for Electronics Manufacturing?" The post was written by Beth Dickinson, a Marketing Consultant for the company TFI, which provides strategic advice and market insights to clients worldwide. The blog post posed the question: What does social media have to offer component distributors, solder-paste makers, and contract manufacturers?

Let’s say that your customer makes the purchasing decisions at an original equipment manufacturer (OEM). They are responsible for an assortment of custom electronics – with ever-changing needs. You are their reputable contract manufacturer (CM) and accommodate their style well, yet you suspect that your customer has made at least one of these comments:

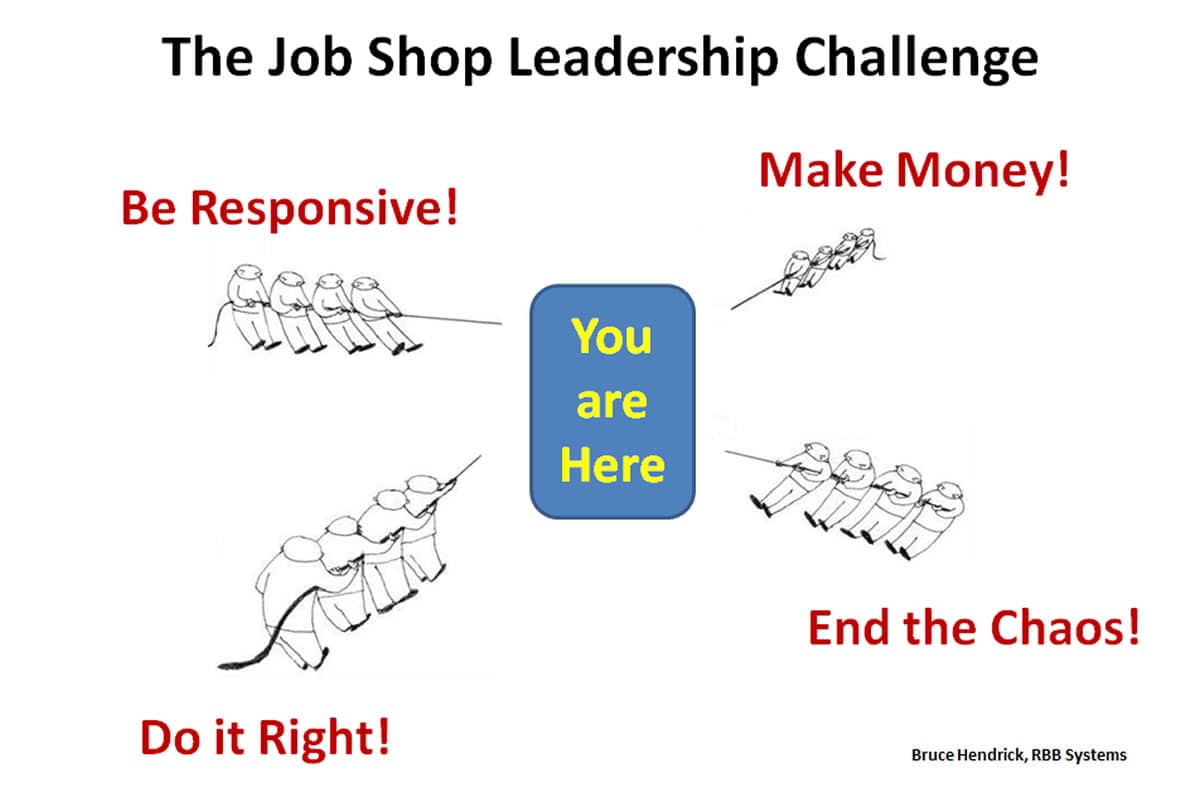

High Wire Act

Even the best run job shops should not underestimate their level of employment paranoia. Sometimes it’s our best people who can get very antsy, very quickly. It doesn’t take much.

In my experience, the more finely-tuned an operation we have, the closer to the edge we are likely to live. Most job shops must:

- Quote aggressively to get the work,

- Squeeze the highest gross margin out of every single job,

- Staff for the “most likely” amount of work (knowing that we will usually be under- or over-staffed),

- Invest in costly equipment and tools to remain competitive… well before we have enough business to truly justify it,

- Pour a massive amount of information into everyone involved, and

- Do the above better than everyone else in the industry.

Sprinkle in a few years of chronic economic pressure and we test even the most resilient co-worker.

To Look Or Not To Look

So if we acknowledge that there is well hidden fear and uneasiness even with good people, good processes, and good business prospects, then we have a choice to make. Do we openly face and discuss the unsettling aspects of our situation or do we shield our employees from the stress and distraction of our business realities so they can focus on their immediate tasks?

I pose this as a viable choice but in truth it is not. Workers have lost their innocence; few are willing to fully commit to organizations unwilling to level with them. Plus, in the absence of actual information, folks assume the worst anyhow. So most progressive job shops tell the truth, the whole truth, and nothing but the truth, whether they are assembling printed circuit boards (pcba’s), building custom airplanes or making deli sandwiches.

The practical question becomes how to quickly convey the shop’s complex status and direction in ways that everyone understands. If I were on a tightrope (not gonna happen), I would have just three urgent demands that would really decide my stress level! Smart job shops figure out how to communicate this information simply and constantly:

- Am I safe and secure right now?

- What can I do to get across my rope (week, month, etc.) safely?

- What upcoming conditions must I deal with?

1-2-3 Go!

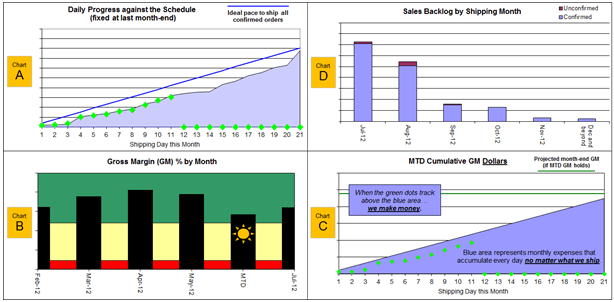

RBB has created a dashboard, published daily by 9:00 a.m., which allows every employee to tell how we are doing and what the near future looks like – while there is still time to change it! Its core content is these four charts. (Real dollar figures are used but have been removed for this publication.) Let me explain.

This was the RBB dashboard on May 31st, 2012. In Chart A, the shaded area shows our planned shipments (USD). Green dots are added daily showing actual results. At a glance we know whether we are ahead or behind schedule. The blue “ideal pace” line reminds us to try to ship the same amount of dollars every day (impossible in a job shop but still a cool goal). Chart A says that in May we stayed very close to schedule and even shipped a few added circuit boards.

Chart B shows the Gross Margin (= price – [material + labor]) of what we are shipping. The MTD (month-to-date) bar is our current status. Simple: Green is best and the higher the better.

Chart C weaves Charts A and B together. Folks understand that gross margin dollars are what we use to pay for the built-in costs of the business. Every morning we see whether our shipment profitability is high enough to cover the fixed costs of the day. If the green dots are above the shaded area on Chart C, we are safely expecting to make money this month. The green line at the top is the projection of monthly profit if we ship everything in the schedule and if the MTD gross margin holds all month. You can see that May was a joy.

Looking ahead then, Chart D shows the actual backlog of booked orders, by month. The pattern here is typical of most job shops: where it looks like demand disappears after the short term. Serious faith that new orders will come in is required (more on this in a future post)! Chart C says that at least June looks busy.

Now fast-forward to mid-June and let’s take another look.

In 5 seconds, we note many things:

- Shipments are on schedule! (Chart A)

- The last day of June will be a VERY busy day. (Chart A)

- So far the gross margin is still in the green but it’s weaker than May. (Chart B)

- At this moment June’s profitability projection looks dicey. (Chart C)

- July’s orders have filled in nicely; August is even looking great. (Chart D)

Bottom line: to finish out June well, we need to make sure everything in the schedule ships and yet do it without raising costs (through overtime, etc.).

And this is the whole point. A simple, powerful dashboard turns every staffer into a business person. Each employee knows what needs to happen to maneuver this month’s tightrope safely. And once we get across, as the new orders dictate, we get to do it all over again.

This ongoing tension is the fun, the thrill, and the stress of the average job shop. Dealing with it as a true team of unified business people – now that’s the real victory. And yeah, it was a squeaker, but we saved June.

Bruce Hendrick has been a leader of major change in corporations and small business alike for the past 25 years; currently he's the owner of RBB Systems and Organizational Development Services, LLC; noted speaker, author, active church member and community volunteer.

It came as a shock when Glinda the Good Witch of the North told Dorothy that she “always had the power” to go back to Kansas. Do you remember her answer when Scarecrow asked why Dorothy had not been told this before? “Because she would not have believed me; she had to learn it for herself.” Which pretty much sums up my life and career.

Like Dorothy, I am compelled to try things my own way before I surrender to the counsel of others. One of these hard lessons was in the need for a company Vision. Oh what pain and strife I could have saved myself and my coworkers! If only!

In Part 1 of this series, I argued that it is vital for any job shop to create a strong separation from its competitors via a crystal clear Mission for existing in the marketplace. But a good Mission can’t do all the heavy lifting; a Vision is also required.

Let’s not spend the time to describe the process for writing a business Vision. Any search on vision will provide all the detail you need on how to write one. The “How” is not really the problem anyway, is it? It’s the “Why.” And the “do I have to.” Here’s what I’ve learned at our small batch electronics company:

- Most job shop leaders already carry in their heads some kind of vision or prediction of the future. It may not be written, but it is there. It’s what fires them up, fuels them to face daily risks, and signals them when the company is off track.

- Employees cannot read the mind(s) of their leaders.

- When employees don’t exactly know what the official company vision is, they naturally make up their own versions.

- These competing visions sound perfectly reasonable but they are often based on bad, outdated, or very individualized assumptions.

- Leaders spend a great deal of their time correcting erroneous decisions or behaviors.

Bottom line: The absence of a galvanizing vision causes our people to take the company in their own preferred direction – in other words, we get a perpetual tug-of-war.

Ruby Slippers

I recommend the simple yet powerful visioning process used by the smart people at Zingerman’s. According to Zingerman’s, all good visions are:

- Inspiring: Others are excited about the vision and want to go there.

- Strategically sound: It might be a stretch, but it is do-able.

- Documented: It’s in writing.

- Communicated: Everyone knows about it.

Now that we know the why and the how, we gotta somehow overcome our reluctance to commit our vision to paper.

Here are some of the excuses I’ve seen (and used) over the years:

Excuse 1: But I’m a lousy writer.

Excuse 2: What if my best people don’t agree with the Vision?

Excuse 3: But I don’t want to choose one future over another. I’m best at rolling with the punches.

Excuse 4: But I don’t want to be held accountable for what I write down!

Excuse 5: Okay but what if I’m wrong?

And this is what I’ve discovered:

Lesson 1: Getting someone to record and transcribe an interview with you works very well.

Lesson 2: Then they are already working against it! You’d better hurry.

Lesson 3: Choose a healthy, vibrant future that is true to your values but still gives you some wiggle room. Then invite lots of voices to flesh it out.

Lesson 4: This is definitely the price you pay, but in the end it is much cheaper than the costs and lost opportunities described above.

Lesson 5: At least you and your team are now building toward a positive, specific future instead of settling for whatever life throws at you. Or doesn’t.

RBB’s world is small batch electronics. Maybe your world is dry cleaning, or custom fabrication, or consulting. You need a Vision as much as we do! Where is your store, factory or office headed? What will it look like in ten years? How will its personality evolve over time? What demons are you fighting now that must be slain if you are to survive?

Describe your Kansas now and you will find, as we have, that you’ve had the power to get there all along!

Bruce Hendrick has been a leader of major change in corporations and small business alike for the past 25 years; currently he's the owner of RBB Systems and Organizational Development Services, LLC; noted speaker, author, active church member and community volunteer.

The JobShopLEAN Conference held on July 10-12, 2012 at The Ohio State University was a fabulous opportunity for professionals in various industries to meet and learn from each other. When one of the conference speakers withdrew, I was honored to step in and share a few thoughts on leadership in job shop environments. Over the next few blog entries, I will touch on the highlights of this presentation.