On last Wednesday’s blog, I outlined the similarities between really strong business systems and really great chili. (For those of you who missed the post, find my world famous chili recipe here.) Today, I focus on how to build out really great business system.

One of the most important aspects of circuit board manufacturing is the ability to efficiently and cost-effectively quote orders. For us at RBB, we swarm to the need as soon as a RFP is received. Many different things simultaneously occur, most of which may sound familiar to fellow small batch electronics manufacturers.

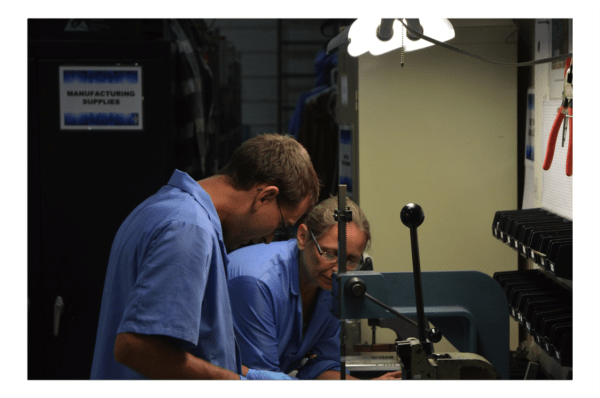

In Part 1 of this series, we shared the behaviors that we have found leads to customer, business, and individual success in an electronics manufacturing environment. As we mentioned before, every employee, regardless of position or length of service, has an obligation to act according to these standards.

RBB recently served as a Global Sponsor and Exhibitor at the Cleveland Engineering Society's Annual Industry and Manufacturing Conference held at Lorain Community College's Spitzer Conference Center.