As you’ve learned in Part 1 and Part 2 of this series, much of the actual work in getting your custom electronics job processed is completed well before it ever goes into production. In this final part of the series, we’ll walk through what to expect during the first production run and the follow up process, and how the relationship is maintained after the receipt of the first order.

In our Part 1 of this series, we discussed the needs assessment and quote preparation stages of the order flow and how important they are to a successful project. The process continues as we enter into the launch phase, which starts once an order is received for a new PCB assembly.

(Or….At Least Help Reduce The Energy Consumption Of The World)

Since the rolling blackouts in California and the Northeast in the early 2000's, California has lead the way towards energy reduction in consumer products; creating initiatives such as the Energy Star Program for appliances such as refrigerators, heating and cooling systems, and computers.

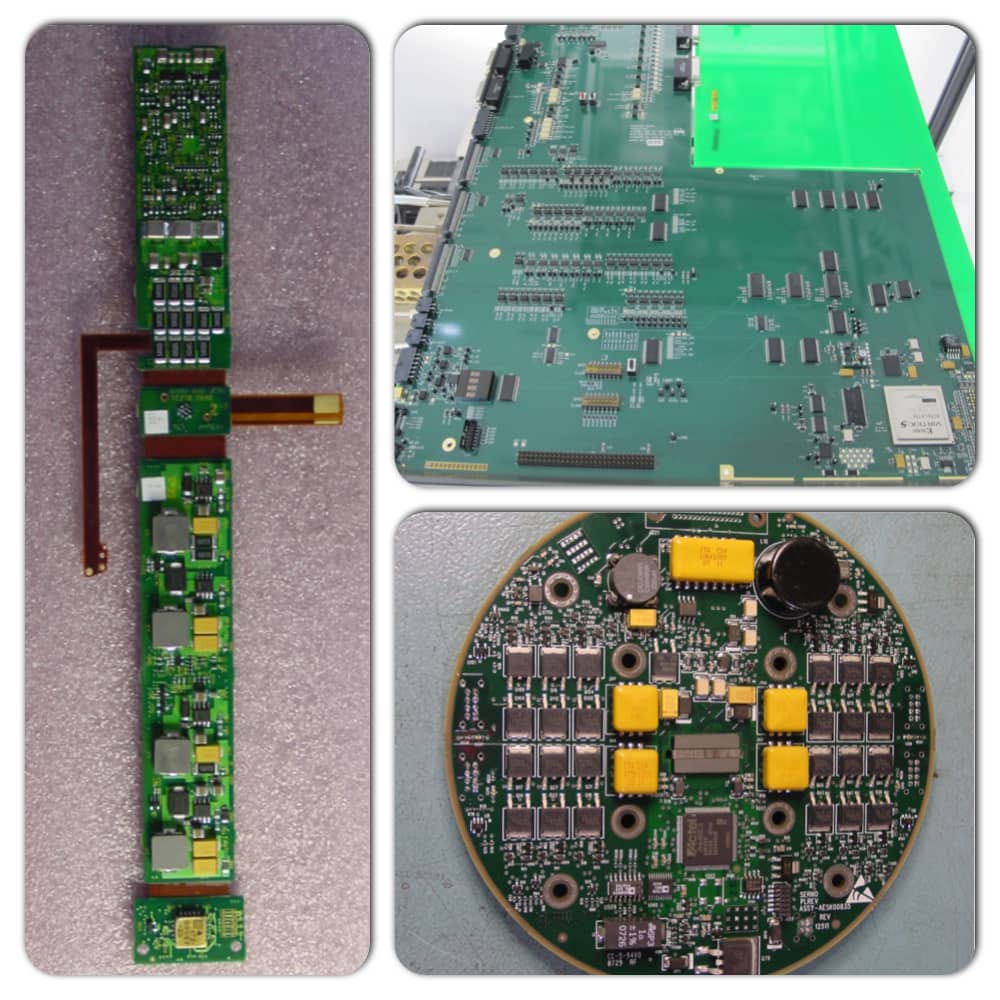

Original equipment manufacturers whose products include circuit board assemblies have an interesting challenge. Whether you're looking to grow your business or sustain a legacy product line, you must be very detailed about the component inventory you carry and the way you plan for the future. The challenge comes in trying to forecast how many pieces you'll need and when. You need to keep circuit boards on hand for your end product - but how many? By managing your inventory and planning for growth effectively, you can better position yourself for success.

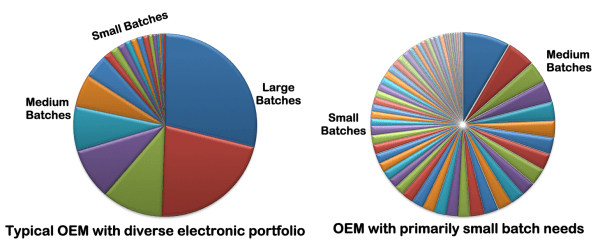

Finding a reliable contract electronic assembler that is qualified to handle your printed circuit board jobs can be a challenge for any business, but when your operation is small or mid-sized, it can feel downright impossible. In order for you to keep up with your production demands, to meet consumer needs and make a profit, you need your PCBs manufactured and returned to you in a timely manner. Unfortunately, if your batch sizes aren't large, you may find that your jobs just don't take priority. But why is this? Why should your orders go on the back burner simply because of their size? Your small jobs matter to you just as much as your high volume work does, but to a high-speed/high-volume CM, this isn’t the case. Because of this, your smaller PCB jobs may be treated as a hassle at best, and an annoyance at worst.

In a company that handles recurring small batch work on printed circuit board assembly, project requirements and specifications can vary a lot. The key to delivering high-quality work in a timely manner is to get the project methodology down to a science. It can't be done without a solid understanding on both sides of the contract: the assembling company must know what the customer needs, and the customer must validate that work undertaken by the company is accurate.

Prototypes – From a Customer’s Perspective

Our team has a great idea for a unique and powerful new product. If we don’t act quickly, someone else will launch a competing device soon. The first company out there usually captures the greatest market share; we’re in a hurry to get some prototype circuit boards built so we can tweak them and get ready for full production.