In Part 1 of this series, we shared the behaviors that we have found leads to customer, business, and individual success in an electronics manufacturing environment. As we mentioned before, every employee, regardless of position or length of service, has an obligation to act according to these standards.

I get a lot of phone calls from entrepreneurs and business owners who are developing a product that has some kind of electronic component. They’re often looking for a new partner to produce parts of the product - or even the entire thing - and are sometimes new to navigating the ways of electronic contract manufacturing.

The world is constantly changing. As with anything, you either go with the flow embracing the change or exhaust yourself trying to swim upstream avoiding it. Why continue doing the same things over and over again when there is a more efficient way? As a small batch electronics manufacturer, we’ve learned to go with the flow and strive for continuous improvement in all aspects of our business.

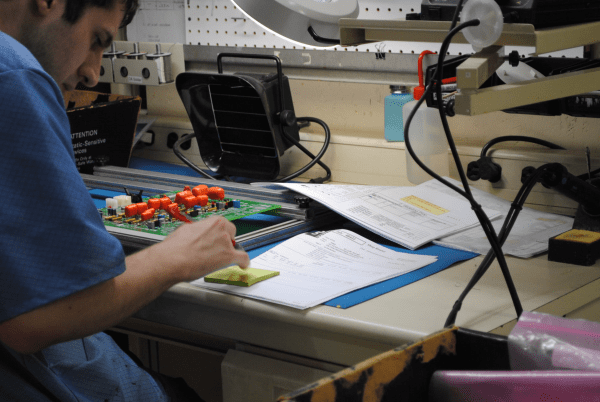

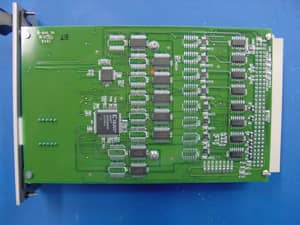

Once in a while, a customer comes to us with a PCB assembly job where they already have parts on hand wanting to know if we can incorporate these existing parts into their job. The parts may have been purchased because a bulk order was needed to get the one or two pieces for a prototype or maybe the customer used to produce the boards in-house and has a remaining inventory of components. Regardless of the reason, most times, we can incorporate these into the job without issue.

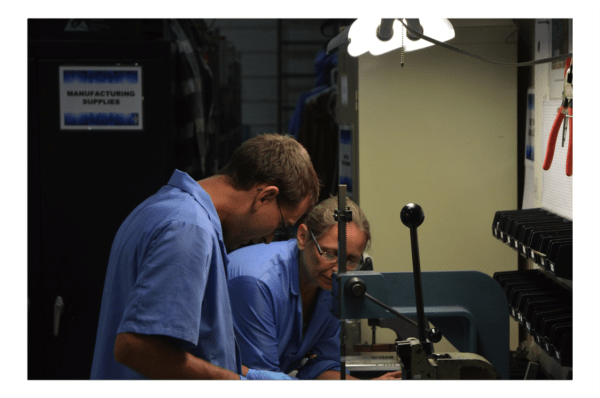

As you’ve learned in Part 1 and Part 2 of this series, much of the actual work in getting your custom electronics job processed is completed well before it ever goes into production. In this final part of the series, we’ll walk through what to expect during the first production run and the follow up process, and how the relationship is maintained after the receipt of the first order.

In our Part 1 of this series, we discussed the needs assessment and quote preparation stages of the order flow and how important they are to a successful project. The process continues as we enter into the launch phase, which starts once an order is received for a new PCB assembly.