On January 3, 2017, and for only the third time since 1973, a new president took over the reins at RBB. In honor of this historic event and Jim Tennant’s much-deserved promotion, I’d like to share a quick story that demonstrates how Jim began strengthening this organization on day one.

Connecting Students with Future Careers in Manufacturing

About Manufacturing Day

On Friday, October 2nd, Wayne County held their second annual Manufacturing Day. A panel of manufacturing employees from the area who have found success within their careers spoke with high school students to provide further knowledge and insights into the industry and where it’s going in the years to come.

Among these speakers, President and CEO of RBB Systems, Bruce Hendrick, shared his experiences with the students.

The development and building of a circuit board assembly can range from a very simple to a highly complex design.

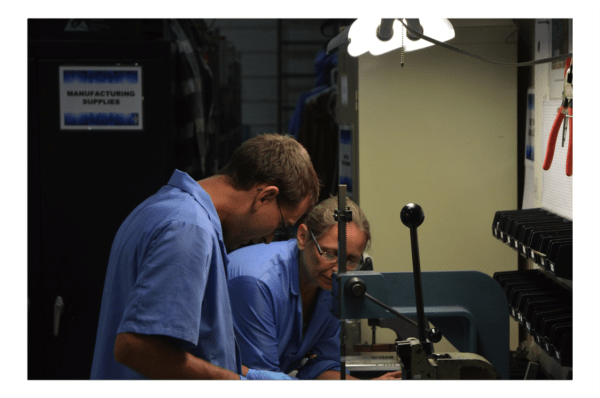

At RBB, all boards, regardless of complexity, undergo a full visual inspection of the components as well as a complete check of the step-by-step instructions on the build. We also offer our customers the option for more advanced functional testing.

For over 40 years, RBB has existed to move heaven and earth to get our recurring small batch customers what they need, when they need it.

In Part 1 of this series, we shared the behaviors that we have found leads to customer, business, and individual success in an electronics manufacturing environment. As we mentioned before, every employee, regardless of position or length of service, has an obligation to act according to these standards.

Recurring small batch electronic assemblies. That's what RBB does, day in and day out. Each of those days filled with a variety of unique jobs, assemblies, customers and suppliers. While it's fun to blog about the ways RBB uses online marketing, the expos we're attending, or the difference between large and small batch contract manufacturers... I found myself very curious about the nitty-gritty details regarding the actual assembly of our circuit boards.

-resized-600.jpg)