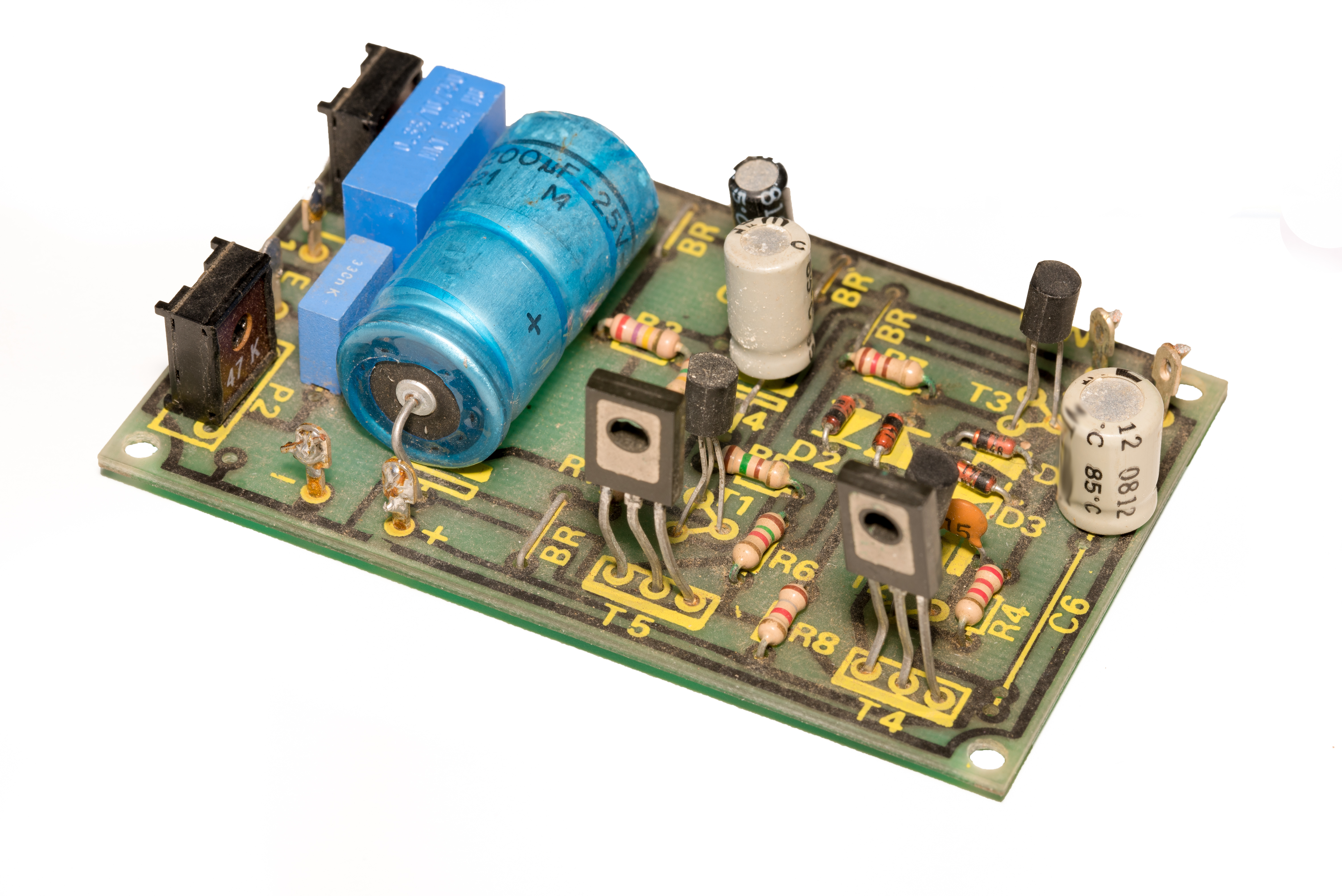

Smart PCB Control Boards

In today's evolving world, combining IoT devices and artificial intelligence (AI) with printed circuit board (PCB) control boards has transformed many industries. The ability to remotely monitor, predict maintenance needs, use autonomous control, improve cybersecurity, and tap into future potentials has greatly changed the way we deal with industrial equipment, automotive systems, and HVAC technology.

This blog talks about the impact of IoT and AI on PCB control boards, discussing real-world examples and emphasizing their potential to shape the future of various sectors.

This blog will explores the power of IoT and AI type boards and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits.

At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.