If you missed either of the two earlier parts of this series, check them out here:

In Part 1 of this series, you heard about the importance of building a deep bullpen consisting of the right pitchers for your particular needs. You can see that each ballgame will require your starter and your reliever coming in at different times to handle the lineup you’re facing. So… now it’s time to figure out the bullpen of pitchers you’ll bring to the game.

If you don’t continue to buy from us, bad things will happen. That’s what your current electronic assembly provider hopes you are thinking.

As a large batch contract manufacturer (LBCM), you have enjoyed a high level of success with your business. In spite of this, though, you may have experienced certain situations in which the help of a small batch job shop (SBJS) could have helped you to operate more efficiently and effectively. While you may know that this is true, many LBCMs are hesitant to enter into a partnership with an SBJS, as they are concerned that it will create customer conflict, and cost them money. Reality couldn't be further from the truth.

The world is constantly changing. As with anything, you either go with the flow embracing the change or exhaust yourself trying to swim upstream avoiding it. Why continue doing the same things over and over again when there is a more efficient way? As a small batch electronics manufacturer, we’ve learned to go with the flow and strive for continuous improvement in all aspects of our business.

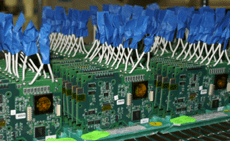

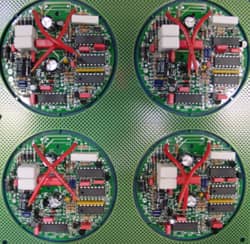

Once in a while, a customer comes to us with a PCB assembly job where they already have parts on hand wanting to know if we can incorporate these existing parts into their job. The parts may have been purchased because a bulk order was needed to get the one or two pieces for a prototype or maybe the customer used to produce the boards in-house and has a remaining inventory of components. Regardless of the reason, most times, we can incorporate these into the job without issue.

As you’ve learned in Part 1 and Part 2 of this series, much of the actual work in getting your custom electronics job processed is completed well before it ever goes into production. In this final part of the series, we’ll walk through what to expect during the first production run and the follow up process, and how the relationship is maintained after the receipt of the first order.