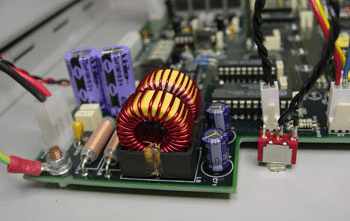

As the Manufacturing Manager at RBB Systems, I oversee the manufacturing of complex circuit boards and custom electronic assemblies, making sure they are built to IPC Standards and are ISO 9001 certified.

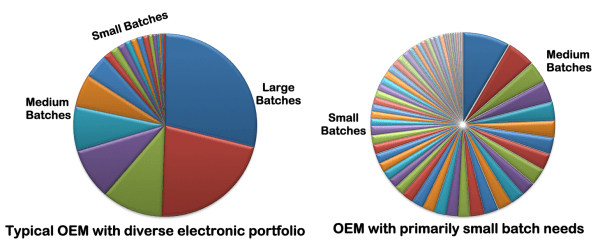

I began my journey with RBB Systems in the summer of 2010. My first home was in the stockroom prepping components and pulling orders for the many different jobs that came through the shop. The one thing I learned very quickly was that no two jobs were the same and the customers were ever changing – benefits to being a small batch electronics manufacturing experts. This was my first experience with this type of work environment. Previously it was mass production. Same parts, same customers. But this was something new that I had never dealt with: many different parts and many different customers.

Talent, class, commitment, and integrity. These leadership hallmarks are exemplified in Wendy Smith, RBB’s General Manager, who begins in May 2013, after 27 years of tireless effort, a new chapter in life. We part as friends and she will be greatly missed. Yet this critical transition will be virtually transparent to customers and the business – and this is a story worth sharing.

At RBB Systems we work with a wide variety of customers that present us the opportunity to build a wide variety of electronic assemblies. This requires us to master a variety of different methods and techniques to manufacture products. Over the past few months the manufacturing department has taken great strides to understand how common and costly mistakes happen, and how to prevent them in the future. This has led us to refine what we have termed the “Kickoff” process.

The Biomedical MEMS and Sensors Conference 2013 held April 16-18 at Lorain County Community College brought presenters, exhibitors and attendees from around the US and the world to focus on MEMS technologies for biomedical applications (BioMEMS).

April 18th 2013

The second day of the BioMEMS and Sensors Conference kicked off with a very interesting breakdown of the steps involved in committing to start up venture which include networking, funding, proof of concept and commercialization. Jumping in with a team of passionate individuals with a culture of positivity is critical. Patience and a little luck can go a long way too!

Inventory Accuracy in a Small Batch Job Shop

Inventory accuracy impacts many different aspects of a successful manufacturing business, especially a Job Shop. Typical consequences of inaccurate inventory are:

Since working in Market Development at RBB, I have been a part of implementing our company's digital marketing plans. Through these online efforts we manage leads, connect with prospects, and develop relationships, while also nurturing and interacting with current customers. All of this is by way of website offers, blog interaction, Facebook updates, tweeting, creating YouTube videos and participating in LinkedIn conversations. Pretty crazy!

Community. Goodwill. Customer service.

Located in the heart of Ohio Amish country, sits a low volume electronics job shop, RBB Systems. You might think it a strange place for a shop that specializes in custom printed circuit boards but it’s not really. It’s an area populated with people who embody the values we look for in our employees – hard-working, reliable, trustworthy, eager to help and willing to move heaven and earth for our customers.