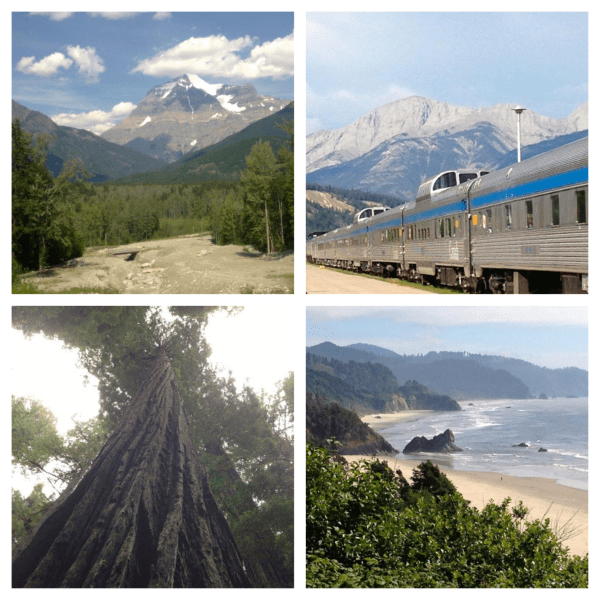

My last post introduced the “off season” concept, where I made a case that anyone who gets paid for what they do (aka a “professional”) needs to occasionally go away and work on their work. In this post I share my own proven formula for making the most of this time away. I swear by the concept and what it has done for me personally, my businesses, and my family. Treat these ideas as guidelines only; you will find what works best when you get out there on your own.

I've been away from the office this week (but not from blogging!) Find out where I've been and how you can make an off season work for you.

If you’re an electronics buyer, some days you may feel like Sarah Connor at the end of The Terminator, the classic 1984 movie. Remember the unstoppable Arnold Schwarzenegger, in all metal form, as he relentlessly chased Sarah through that factory of moving equipment? He simply refused to die!

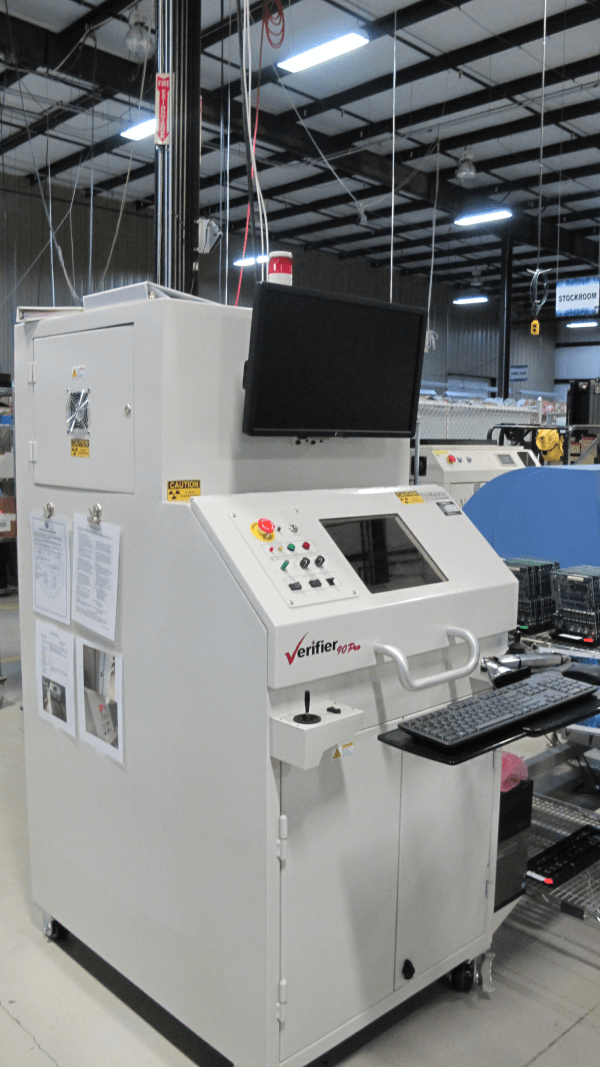

Function of the X-ray Machine

An X-ray machine in micro-assembly inspection is used to see through the first layers of an integrated circuit to inspect the quality of a ball grid array (BGA). It allows us to see and inspect what we wouldn’t be able to otherwise. More specifically, we could see defects in BGA chips, detect possible counterfeit parts, and inspect our special potted assemblies, along with other applications.

In Part 1 of this discussion we discussed 5 battles that small batch job shops like RBB need to fight if and when they occur. Those situations are:

“We exist to move Heaven and Earth to get our small batch customers, what they need, when they need it.” “Even if it blows up the schedule.” A bit of humor, but we’ve all been there, the customer calls and says that they need “WHAT” by “WHEN”. In today’s LEAN electronic manufacturing environment, short lead times and quick turns are essential to our customers. It’s now up to us to make it happen.

Note: This post is adapted from a similar one I wrote for the ODS blog which is devoted to leadership, communication and trust.

Like any business, small batch shops like RBB have many things we can improve upon all the time. (And the minute we don’t admit it signals the beginning of dangerous complacency!) It’s a growing challenge since most low-volume electronics manufacturing companies face intense competition and so seem hooked on instant answers and urgent innovation. Employees, regardless of their formal authority face enormous pressure to address everything that stands in the way of reaching the company's goals. Or they often think they do.

-resized-600.jpg)