Tailoring Solutions

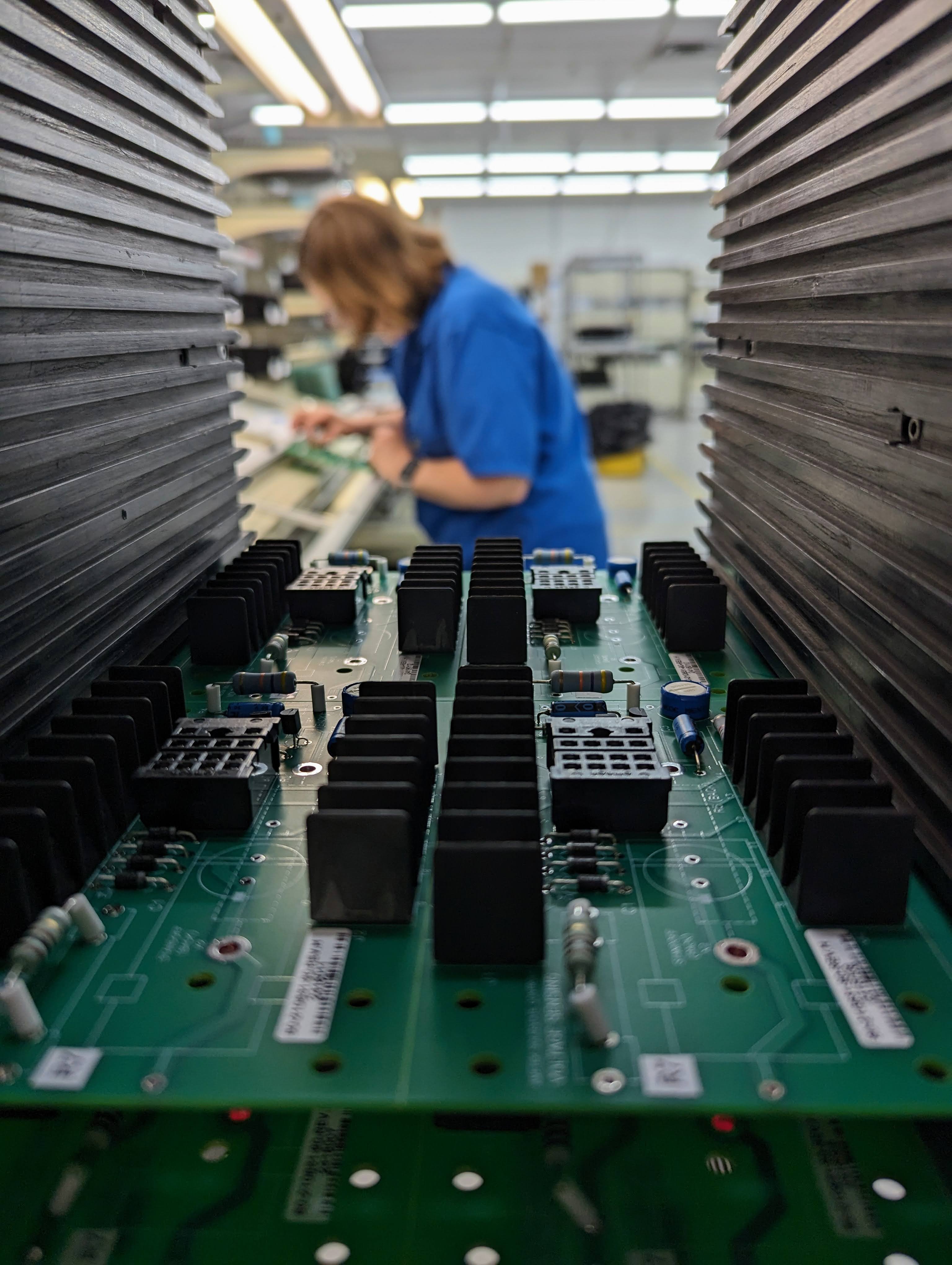

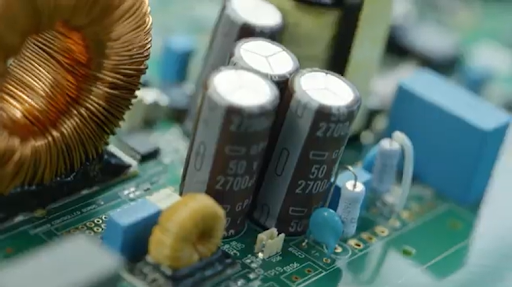

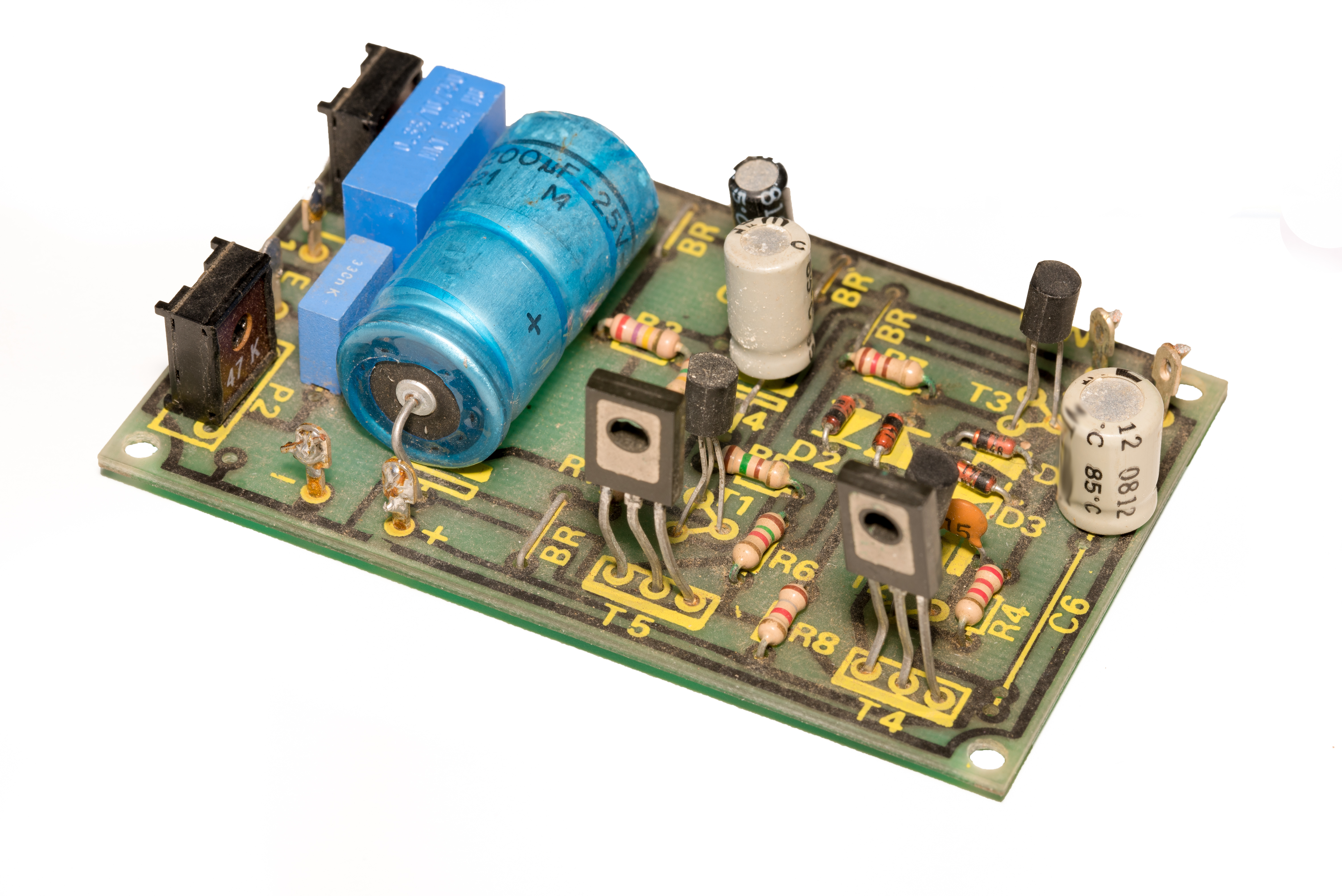

Custom electronics manufacturing is a great chance for businesses to design and develop products that will meet their needs in the best way possible. This is because when a company works with a specialized manufacturer, it is able to achieve flexibility in design, scalability in production and differentiation in the market.

This blog will explores tailoring custom electronics manufacturing with solutions, benefits and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits.

At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.

.jpg)

.jpg)