Optimizing SMT Prototype Boards for Production.

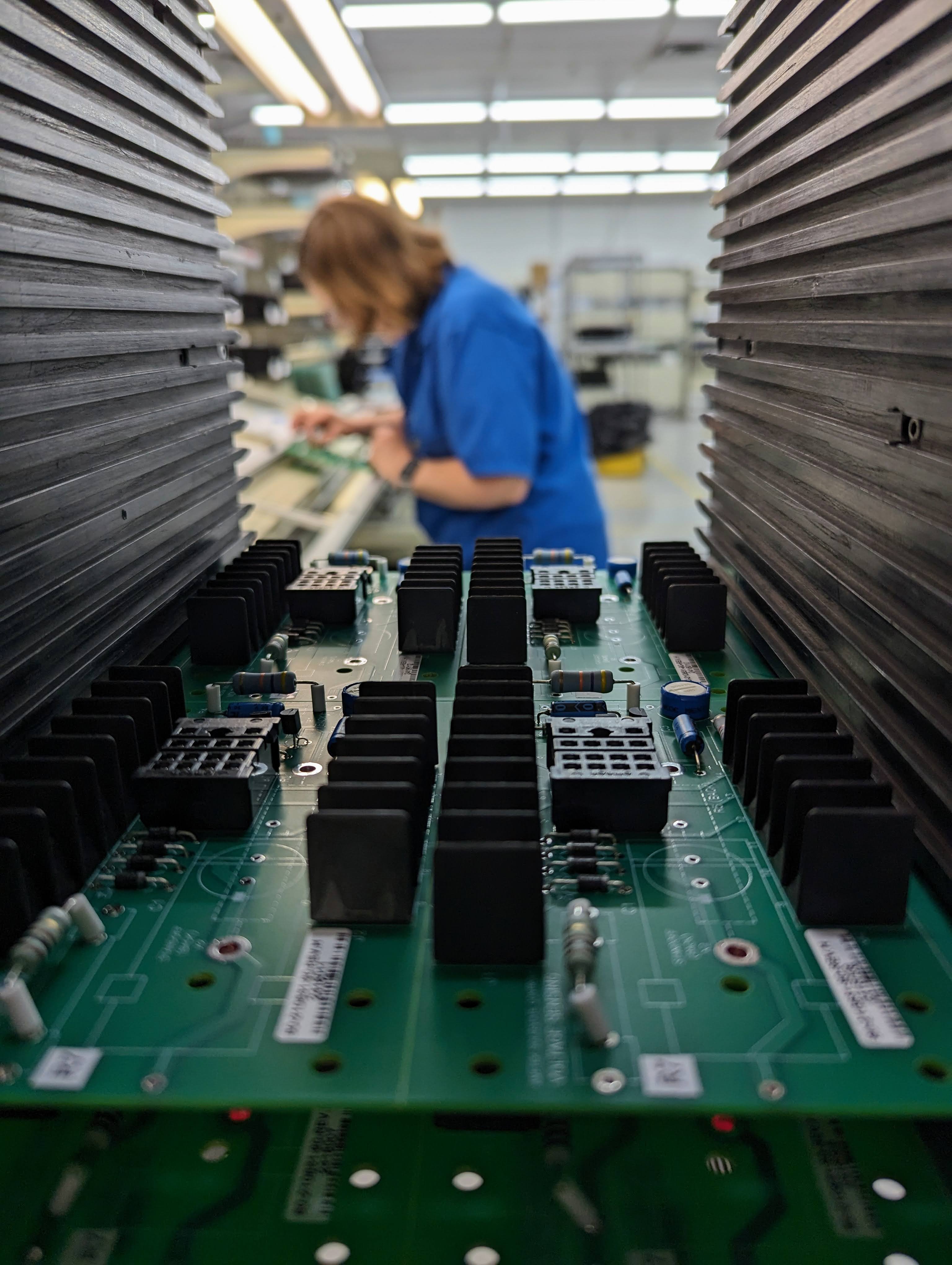

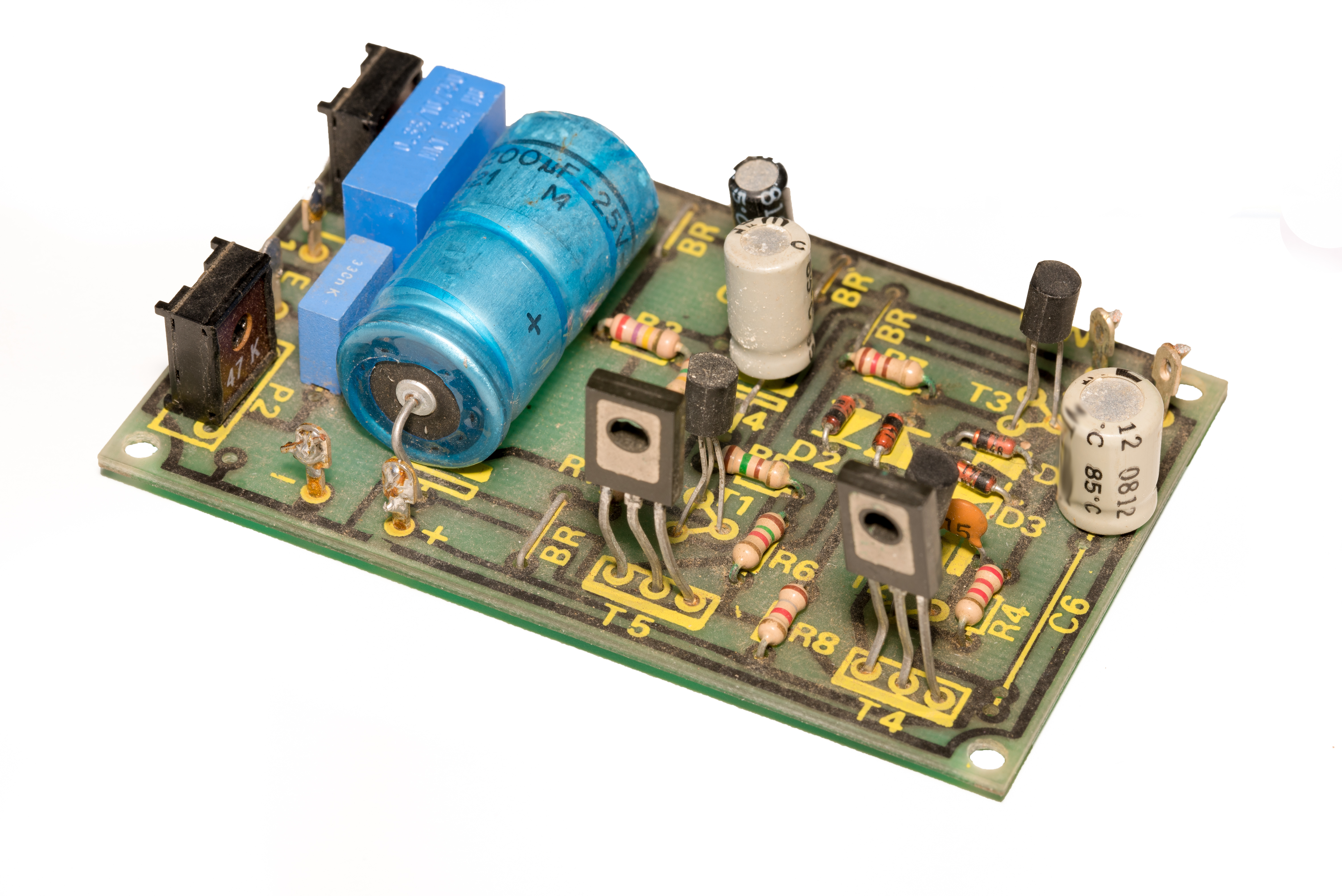

When designing Surface Mount Technology (SMT) prototype boards to move towards mass production, manufacturability becomes a crucial consideration. Every aspect, from component placement to soldering and assembly tolerances, is meticulously optimized to align with the ultimate goal of mass production.

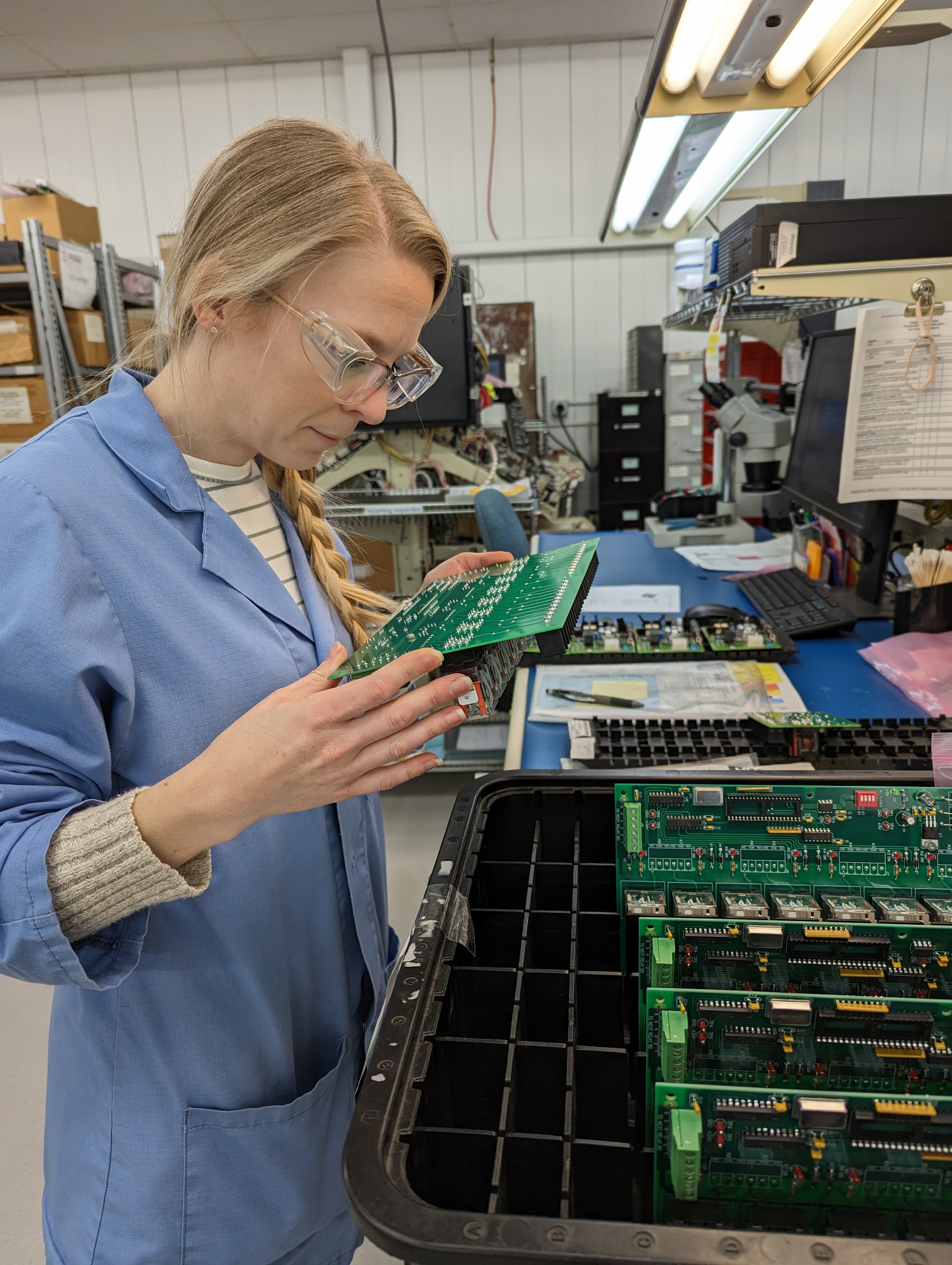

At RBB, we recognize the significance of this process and emphasize the necessity for close collaboration between design engineers and our manufacturing team during the transition from prototyping to production. This blog will explore the techniques and approaches essential for achieving outstanding SMT prototype boards, shedding light on the pivotal aspects that define manufacturability.

This blog will explores the optimizing of SMT proto type boards and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits.

At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.

.jpg)

.jpg)