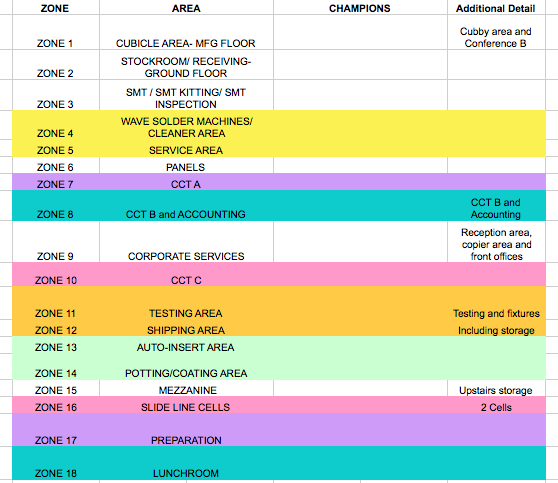

RBB’s 6S Program

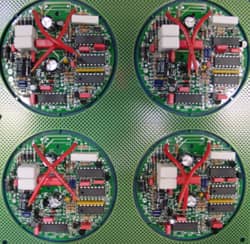

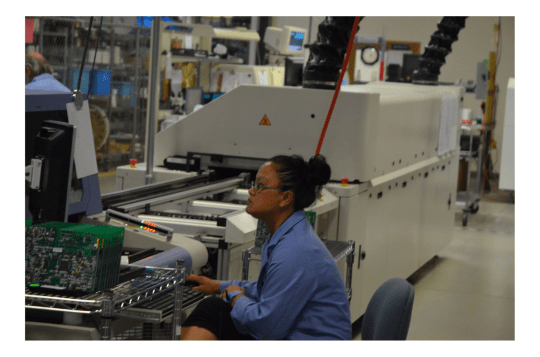

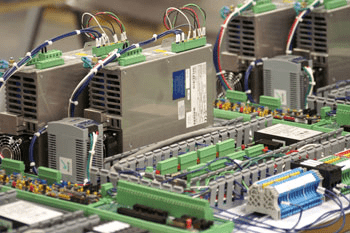

Everyone at RBB feels a responsibility for keeping our facility and everything (and everyone!) in it in good working order. We look for every possible way to ensure that the custom electronic boards that leave our facility are pristine, and have been built efficiently and exactly to our customer’s specifications. To do that, we need clean areas so we can focus on the job at hand. We need a well-maintained facility and a dedication to keeping personal spaces as neat as possible.